| |

TM 10-3930-671-24

F.

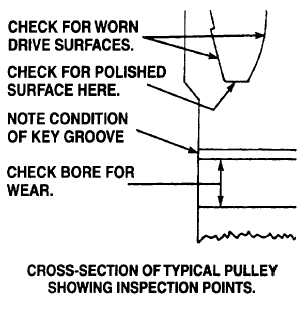

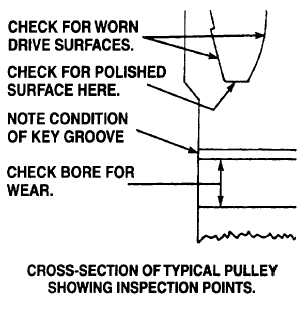

Examine the pulley for wear or fracture and

inspect key-way for wear. Check the fan for bent

or missing fins and possible wear of the

mounting hole from running loose. Reuse if in

good-condition (Figure No. 49).

FIGURE NO. 49.

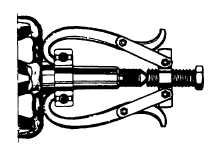

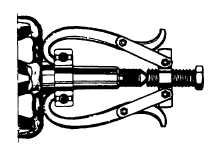

FRONT BEARING REMOVAL - Use bearing puller to

pull bearing off shaft, if the bearing is to be reused, puller

must contact inner race only (Figure No. 50).

FIGURE NO. 50.

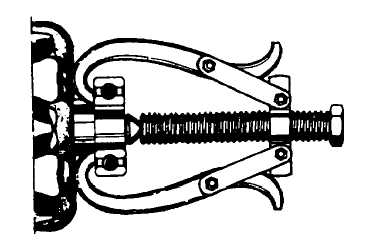

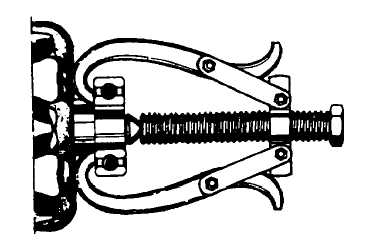

REAR BEARING REMOVAL The rear bearing is a press

fit to the rear rotor shaft. Any commercial bearing puller

may be used to remove the rear bearing from the shaft

(Figure No. 51). Pull on the inner race if bearing is to be

reused.

FIGURE NO. 51.

When replacing alternator bearings, it is essential that

the replacement bearing be equal to original equipment.

The TA bearings have special clearance between races

and bearings, plus they are lubricated with high

temperature BRB No. 2 or Andok 260 grease. Refer to

Parts List for recommended bearings.

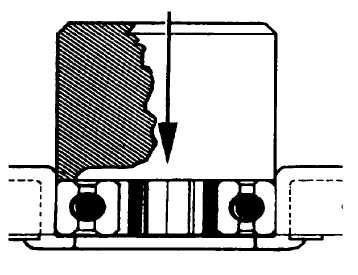

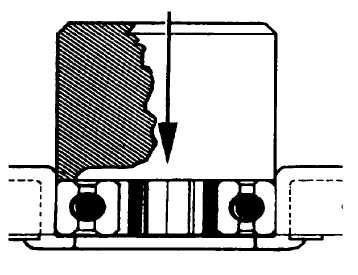

ASSEMBLY OF FRONT HOUSING - Make certain that

bearing cavity in front housing is clean and felt dust seal

is installed in recess. Press bearing into housing, using

driver tool that exerts pressure on outer race only.

Apply only sufficient pressure to seat bearing, against

bottom of cavity (Figure No. 52). Install bearing retainer,

secure with the attaching screws.

FIGURE NO. 52.

F-293

|