| |

TM 10-3930-671-24

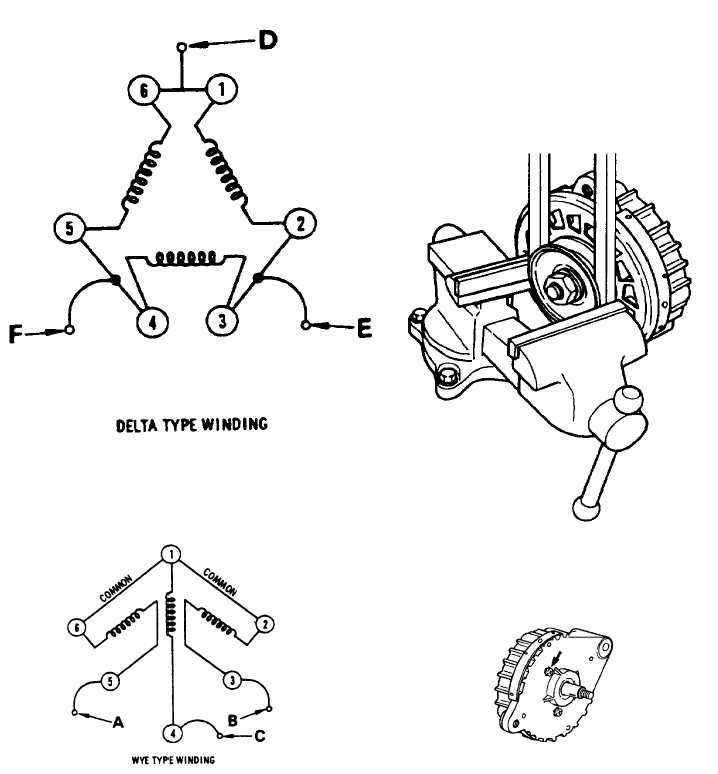

FIGURE NO. 41.

The Wye circuit used in 22 ampere TA alternators,

provides a common winding termination, plus three leads

to connect the stator to the rectifying diodes (A - B - C)

(Figure No. 42).

FIGURE NO. 42.

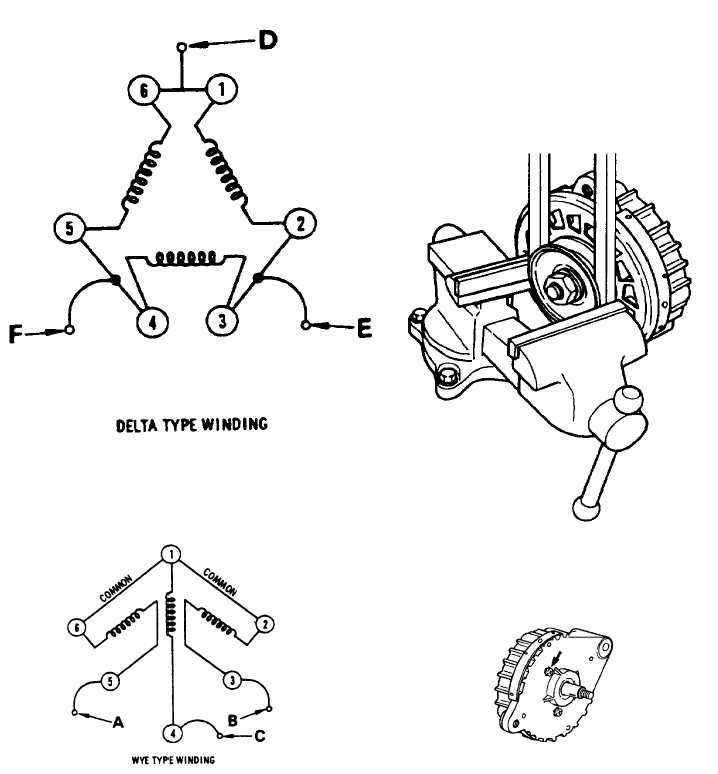

PULLEY REMOVAL - The various pulleys applicable to

the TA alternator, are of a slip type fit. A Woodruff key is

incorporated on the rotor shaft for "keying" of the pulley

and fan. To remove the nut and lockwasher, clamp

the pulley in a vise, using an old oversized belt to protect

the pulley from damage by the vise jaws (Figure No.

43).After pulley mounting nut, and split lock-washer have

been removed, the alternator should "pull" back and

away from pulley.

NOTE

Should pulley be "frozen" to rotor

shaft, while supporting alternator,

strike end of shaft with a wooden

mallet, plastic hammer or a special

puller to break pulley free from shaft.

FIGURE NO. 43.

ROTOR REMOVAL FROM FRONT HOUSING -

1.

Remove three 8-32 Phillips head, machine

screws and lockwashers from the front housing

(Figure No. 44).

FIGURE NO. 44.

F-291

|