| |

TM 10-3930-671-24

STATOR REMOVAL-

1.

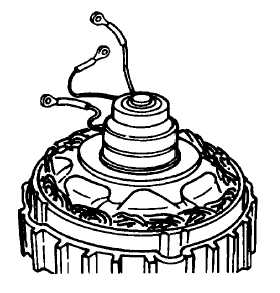

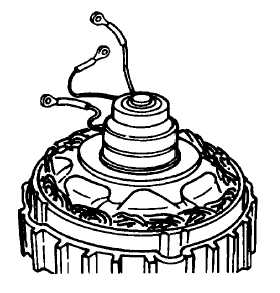

Grasping the stator, apply pressure to separate

stator from housing (Figure No. 37).

FIGURE NO. 37.

All connections of the TA stator are either welded or

crimped and should not be taken apart. Do not attempt

to solder replacement leads to the ends of the windings.

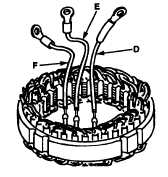

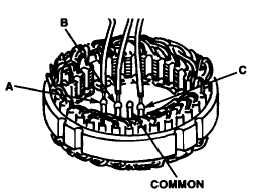

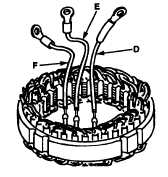

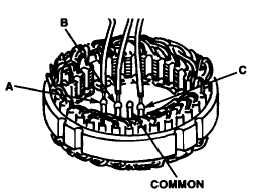

The test procedure for each type stator is different, due

to the fourth test point on the Wye stator. The objective

is the same. The tests must indicate that: (1) all

windings are a complete circuit. (2) They are not short

circuited to each other. (3) The windings are not

grounded. Discoloration of the enamel on the windings

is evidence of overheating and may cause a shorted

condition. Test stator leads as indicated in Figure No’s.

38 & 39.

FIGURE NO. 38.

FIGURE NO. 39.

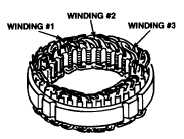

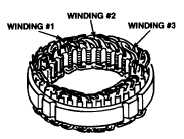

STATOR SERVICE OPERATIONS - The alternator

stator consists of three individual windings wound on a

common core or lamination. The lamination is Insulated

tor durability (Figure No. 40).

FIGURE NO. 40.

The usual reference to alternator stators concerns the

method of terminating the ends of the three windings.

They may be connected in a Wye, or a Delta circuit

(Figure No’s. 41 and 42). The Delta circuit used in 30

and 45 ampere TA alternators, does not have the

common termination, just three connecting leads for the

rectifying diodes (D - E - F), (Figure No. 41).

F-290

|