| |

TM 10-3930-671-24

3.

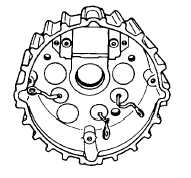

Remove the three black leads from the heat sink

screws and gently push the heat sink out of the

housing. Observe loose leads as plate is being

removed, so as not to damage leads (Figure No.

28).

NOTE

Three mica insulators are set against

the inside of the rear housing and

insulate positive heat sink from rear

housing (Figure No. 28). The mica

insulators are retained by a recess in

the rear housing, plus the use of

silicon grease.

FIGURE NO. 28.

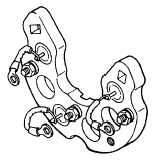

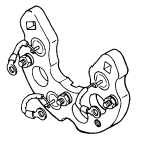

OUT OF CIRCUIT RECTIFIER DIODE TEST - If a

commercial alternator rectifier diode tester is available,

follow manufacturer’s instructions to test all diodes. Do

Not Use 120 Volt AC test lamp.

A 12 Volt battery operated test lamp may be used if a

commercial tester is not available. Connect one test

lead to diode heat sink, the other to each diode wire

terminal, Figure No. 29, then repeat test with test leads

reversed. Lamp should light with leads in one position,

but should not light with test leads reversed. All diodes

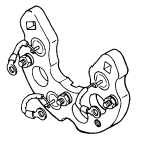

in heat sink (Figure No. 29) or rear housing (Figure No.

30) should show the same results.

FIGURE NO. 29.

FIGURE NO. 30.

If lamp lights, regardless of how test leads are switched,

the diode is shorted. If lamp fails to light in either test,

the diode is open. Replace defective diodes, observe

correct polarity by color of stamping used to list part

number on diode.

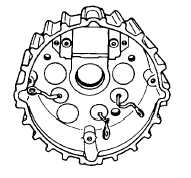

REPLACING DEFECTIVE RECTIFIER DIODES-

Note, head of output stud, is a metal to metal contact.

Figure No. 31 shows three positive, rectifier diodes, and

terminal studs assemblied in the positive heat sink.

FIGURE NO. 31.

F-288

|