| |

TM 10-3930-671-24

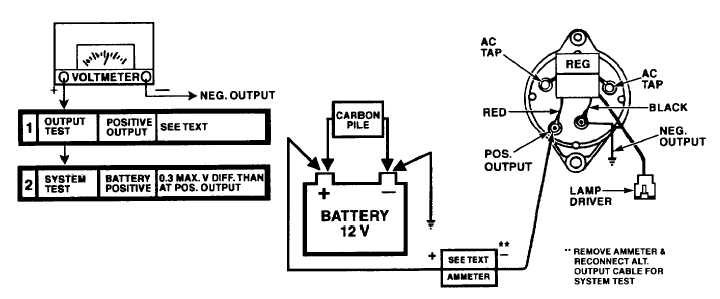

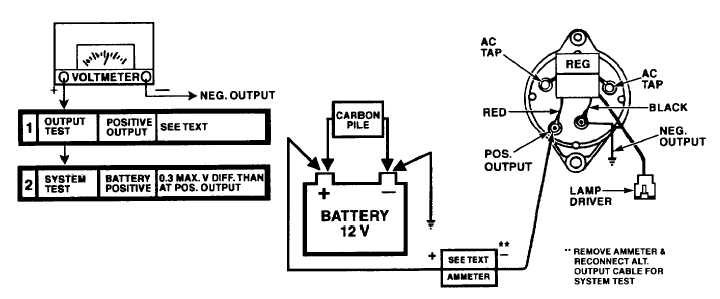

FIGURE NO. 17.1.

ALTERNATOR OUTPUT AND SYSTEM TEST (45 Amp Systems) - This test will determine if the alternator is capable of

producing a minimum rated output. Position load control knob of carbon pile to the "OFF" position prior to connecting

leads to battery terminals. The test requires that a test ammeter be set to the 0-200 ampere scale, and connected in

series with the alternator positive output terminal and battery positive terminal, as shown in Figure No. 17.1.

Start the engine and allow it to run for a few minutes to stabilize component temperatures. Adjust engine speed to 3000-

5000 alternator rpm. Apply carbon pile load to the battery to induce highest alternator current output.

Note voltage output. Minimum acceptable (hot) alternator output should be 41-45 amperes. Output voltage must remain

between 13.0 and 15.0 volts.

If alternator cannot produce the required output, remove from engine and rebuilt. Reduce carbon pile load on battery

immediately after testing to avoid discharging battery.

System voltage drop, between the alternator and the battery, is tested with the alternator producing 10 amperes. The

maximum allowable voltage drop, between alternator and battery is .3 (three tenths) volt. Excess voltage loss may require

cleaning and tightening of all circuit connections or replacement of output cables between the alternator and the battery.

ALTERNATOR

DISASSEMBLY

&

COMPONENT

TESTS

BRUSH ASSEMBLY REMOVAL

1.

Remove regulator to gain access to the brush

assembly cover (Figure No. 18).

FIGURE NO. 18.

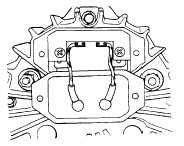

2 With brush assembly cover pulled down and away

from back housing, remove two 8 X 1/2" tapping

screws retaining brush assembly to housing

(Figure No. 19).

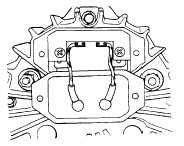

FIGURE NO. 19.

F-285

|