| |

TM 10-3930-671-24

SECTION 5 REASSEMBLY

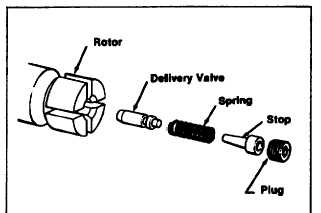

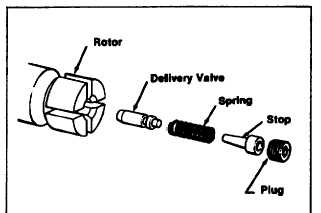

STEP 1 Rinse rotor thoroughly in clean fuel or calibrating

oil. Place the rotor on rotor support and secure rotor

support in vise. Install the delivery valve to its bore using

extractor. Make sure it slides freely in its bore.

NOTE

Do not mistake slight interference of the retractor

collet in the bore for delivery valve sticking. If the

valve is not secured straight and tight in the

retractor collet, the collet diameter can drag in the

rotor bore.

Install delivery valve spring and a new delivery valve stop

to the rotor bore (Figure 5.1). Installation of a used stop

can result in leakage and low output at cranking speeds.

Start the delivery valve retaining screw into the bore

using the hex end of the delivery valve Extractor. Tighten

the screw to the specified torque.

Excessive tightening of this screw may cause

seizure of the hydraulic head and rotor assembly.

Insufficient torque may cause leaking and hard

starting.

FIGURE 5.1.

DELIVERY VALVE REPLACEMENT

Delivery valves of various retraction values are used for

different applications. Correct part numbers are found on

individual pump specifications. The letters ’OV" etched

on the base of the rotor indicate a .001’ oversize delivery

valve bore. A rotor so marked must use a .001" oversize

delivery valve. Part numbers for both standard and

oversize

valves

are

listed

on

individual

pump

specifications. The oversize valve is also identified by

blackening

on

both

ends

and

in

the

groove

on the delivery valve shank.

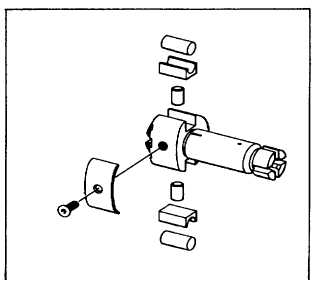

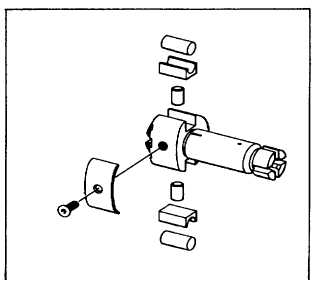

STEP 2 Remove the rotor from the holding fixture and

submerge it in clean calibrating oil. Install the pumping

plungers and check them for freedom of movement.

Assemble the leaf spring, leaf spring adjusting screw and

shim (if used) to the rotor (Figure 5.2).

FIGURE 5.2.

PLUNGER REPLACEMENT

Since the plungers are positioned centrally in the bore

during operation and their travel is extremely short, wear

of plungers is negligible. Replacement, however, may be

made in instances where rust or damage in handling has

occurred. Plungers of any given nominal diameter are

graded in four select fit sizes: A, B, C, and D. The rotor is

etched with the letter indicating bore size. This mark is

found on the base of the rotor. If plunger replacement is

required, check the size designation on the rotor and use

the plunger of corresponding part number as indicated

on individual specifications. For example: A .330"

diameter plunger bears basic part No. 11076 and the

graded sizes, A through D, bear part No. 11077 through

11080, respectively. The replacement plungers for a

.330’ diameter plunger pump with a rotor marked C"

would be part No. 11079. Always refer to correct

individual specifications for part numbers.

NOTE

A limited number of pumps will have a “-2” etched

on the rotor following the letter grading code. This

mark indicates a .002" (.05rm) oversize plunger bore.

Replacement should be ordered according to the

oversize plunger group shown on individual

specifications.

F-235

|