| |

TM 10-3930-671-24

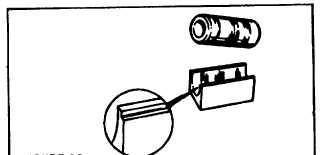

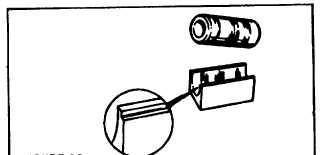

6. Cam Rollers and Shoes Check each roller in its shoe

for freedom of rotation. Inspect the top edge of each

shoe, where retained by the leaf spring, for chipping or

excessive wear. Inspect roller and shoe for abrasive

wear patterns as illustrated (Figure 4.6).

FIGURE 4.6.

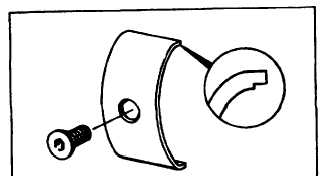

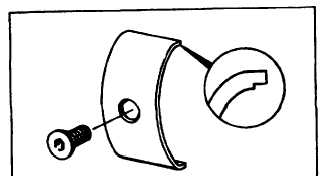

7. Leaf Spring and Screw Check for excessive wear at

points where the spring contacts the radii on the rotor

and along the steps that retain the roller shoes (Figure

4.7). Check the adjusting screw for tightness in the rotor.

FIGURE 4.7.

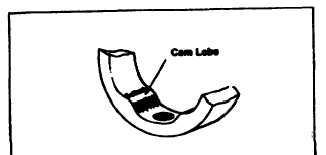

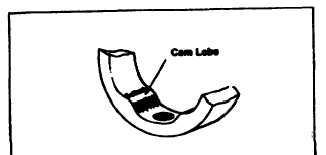

8. Cam Since only the working portions of the lobes on

the inside diameter are ground, any tool marks between

lobes should not be considered as damage. The mottled

appearance of the cam is from heat treatment rather

than from operation. Carefully inspect the cam lobes and

edges of all flat surfaces. If there is evidence of spalling

or flaking out, replace with a new cam (Figure 4.8).

FIGURE 4.8.

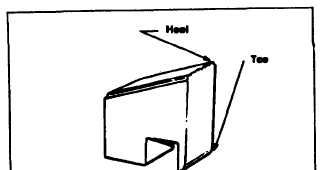

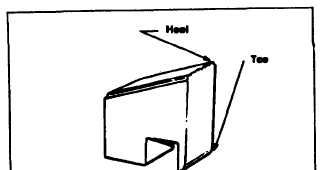

9. Governor Weights Check pivot points (heel and toe)

of all weights for excessive wear (Figure 4.9).

FIGURE 4.9.

10. Transfer Pump Blade Inspect with the utmost care.

Check for chipping on any of the edges, including spring

bore edges, pitting, imbedded foreign particles or scoring

on the rounded edges. Determine blade wear by

measuring the length (0.538" min. [13.67mmD. Inspect

flat surfaces visually for deep scores (Figure 4.10). f any

discrepancies are noted, replace both blade sets and

springs.

FIGURE 4.10.

F-234

|