| |

TM 10-3930-671-24

C.

SUPPLEMENTARY INSPECTION

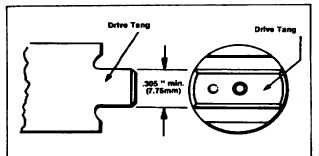

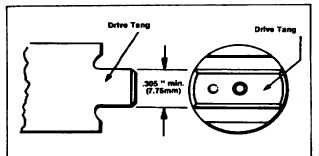

1. Drive Shaft Measure the distance across the flats of

the drive tang which must not be less than .305"

(7.75mm). The shaft diameter in the drive shaft seal area

must be free of nicks and scratches for the seals to

function properly. Moderate shaft wear from the seal lips

is normal (Figure 4.1).

FIGURE 4.1.

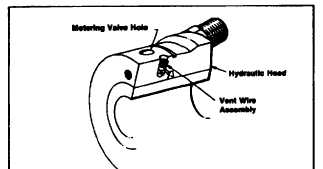

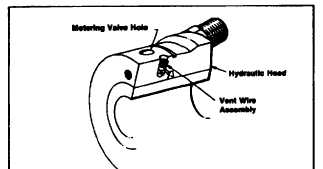

2. Hydraulic Head Check the vent wire assembly in the

hydraulic head for freedom of movement. If the wire is

free, flush the head and blow out all passages with clean,

dry air (Figure 4.2). If vent wire is stuck in screw

assembly, remove and replace after a thorough cleaning

of the assembly and hydraulic head passage.

Do not immerse this head in solvent for extended

periods; sealant damage will result.

FIGURE 4.2.

3. Distributor Rotor Examine the radii contacted by the

leaf spring and the tang slot for excessive wear. Check

all slots, charging and discharge ports for chipping of

edges or dirt, and the rotor shank for major

scratches. Slight erosion on the edge of the discharge

port is considered normal. If damage or excessive wear

is apparent, the head and rotor must be replaced as a

matched unit. Final check for excessive wear on the

rotor should be performed on the test stand by checking

for minimum cranking delivery.

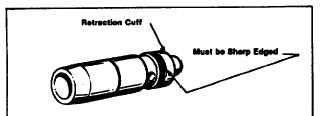

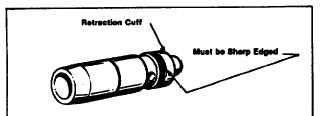

4. Delivery Valve Inspect delivery valve retraction cuff

for chipping or erosion of edges (Figure 4.4).

FIGURE 4.4.

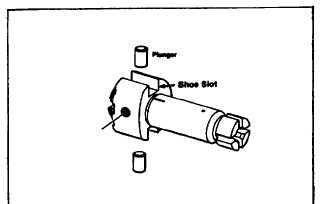

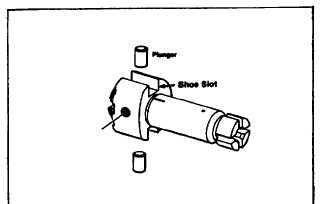

5. Plungers While holding the rotor under clean oil,

insert the plungers into their bore. With thumb and

forefinger over the shoe slots, tilt from side to side

several times to determine complete freedom of

movement. Interchanging or reversing their initial

positions may be necessary, as these are matched parts.

If the plungers are sticking, but not visibly damaged,

clean both plungers and bore with a soft brush and a

solvent such as lacquer thinner or acetone (Do not force

plungers into their bore and do not handle rotor shank.)

(Figure 4.5).

FIGURE 4.5.

F-233

|