| |

TM 10-3930-671-24

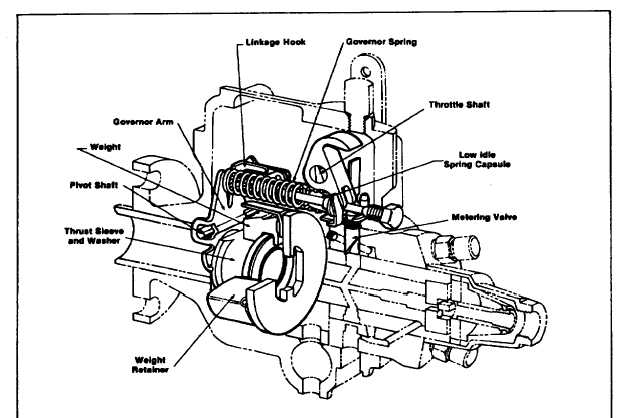

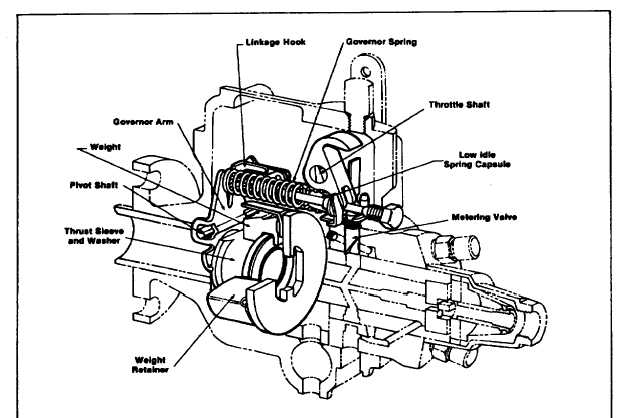

FIGURE 1.11.

J.

AUTOMATIC ADVANCE-SPEED

RESPONSIVE

The Roosa Master design permits the use of a simple,

direct-acting hydraulic mechanism, powered by fuel

pressure from the transfer pump, to rotate the cam

slightly

and

vary

delivery

timing.

The

advance

mechanism advances or retards start of fuel delivery in

response to engine speed changes. In most injection

systems, the actual beginning of delivery of fuel at the

nozzle will start later (in engine degrees of rotation) as

the speed increases.

Compensating inherent injection lag improves highspeed

performance of the engine. Starting delivery of fuel to the

nozzle earlier when the engine is operating at higher

speed ensures that combustion takes place when the

piston is in its most effective position to produce

optimum power with minimum specific fuel consumption

and minimum smoke.

The advance pistons located in a bore in the housing

engage the cam advance screw and move the cam

(when fuel pressure moves the power piston) opposite

the direction of rotor rotation (Figures 1.12 and 1.13).

Fuel under transfer pump pressure is fed through a

drilled passage in the hydraulic head which registers with

the bore of the head locating screw. Fuel is then directed

past the spring-loaded ballcheck in the bore of the head

locating screw. It then enters the groove on the outside

diameter of the screw which registers with a drilled

passage in the housing leading to the power piston side

of the automatic advance assembly.

A groove around the power piston plug and a drilled

passage allow the fuel to enter the advance piston bore.

Fuel pressure against the piston must overcome the

opposing spring force plus the dynamic injection loading

on the cam in order to change the cam position. The

spring-loaded ballcheck in the bore of the head locating

screw prevents the normal tendency of the cam to return

to the retard position during injection by trapping the fuel

in the piston chamber. When engine speed decreases,

the hydraulic pressure is reduced and the spring returns

the cam to a retarded position in proportion to the

reduction in speed. The fuel in the piston chamber is

allowed to bleed off through a control orifice located

below the ballcheck valve in the head locating screw.

At low speeds, because transfer pump pressure is

comparatively low, the cam remains in the retarded

position. When engine speed increases, transfer pump

F-221

|