| |

TM 10-3930-671-24

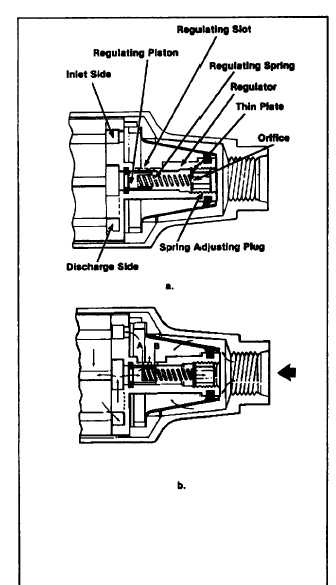

pressure on the piston is opposed by the regulating

spring, the delivery pressure of the transfer pump if

controlled by the spring rate and size of the regulating

slot "A." Therefore, pressure increases with speed.

A high-pressure relief slot ’B" is incorporated in some

regulators as part of the pressure regulating slot to pre

vent excessively high transfer pump pressure, if the

engine or pump is accidentally overspeeded.

FIGURE 1.6.

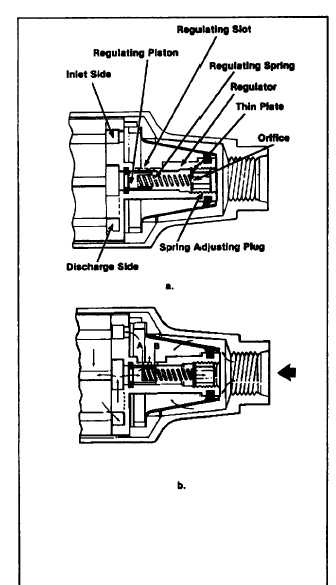

VISCOSITY COMPENSATION

The DB2 transfer pump works equally well with different

grades of diesel fuel and varying temperatures, both of

which affect fuel viscosity. A unique and simple

feature of the regulating system offsets pressure

changes caused by viscosity difference. Located in the

spring adjusting plug is a thin plate incorporating a

sharpedged orifice. The orifice allows fuel leakage past

the piston to return to the inlet side of the pump. Flow

through a short orifice is virtually unaffected by viscosity

changes. The biasing pressure exerted against the back

side of the piston is determined by the leakage through

the clearance between the piston and the regulator bore

and the pressure drop through the sharpedged orifice.

With cold or viscous fuels, very little leakage occurs past

the piston. The additional force on the back side of the

piston from the viscous fuel pressure is slight. With hot

or light fuels, leakage past the piston increases. Fuel

pressure In the spring cavity increases also, since flow

past the piston must equal flow through the orifice.

Pressure rises due to increased piston leakage and

pressure rises to force more fuel through the orifice. This

variation in piston position compensates for the leakage

which would occur with thin fuels and design pressures

are maintained over a broad range of viscosity changes.

E.

CHARGING AND DISCHARGING

Charging Cycle

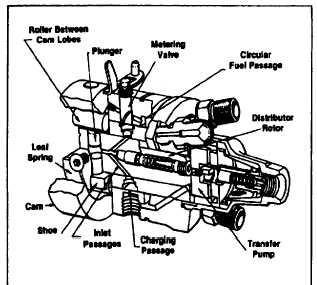

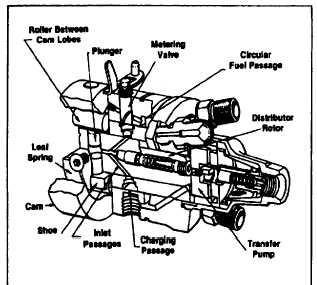

As the rotor revolves (Figure 1.7), the two inlet passages

in the rotor register with ports of the circular charging

passage. Fuel under pressure from the transfer pump,

controlled by the opening of the metering valve, flows

into the pumping chamber forcing the plungers apart.

FIGURE 1.7.

F-218

|