| |

TM 10-3930-671-24

Fuel Injector Testing

WARNING

Bodily Injury may result during this procedure if

care is not taken. Keep hands and face away

from nozzle spray. The high velocity of oil spray

may

puncture

the

skin

and

cause

blood

poisoning. If injured by escaping fluid, get

medical attention at once.

NOTE

Injection should not be disassembled unless

testing shows that cleaning or other servicing Is

needed.

Injectors are tested by using a special hydraulic injector

tester, bolted to a bench with a small fuel oil supply tank

with filter included to ensure that only clean fuel enters

the injector. A high-pressure injection line is used to

connect the outlet of the tester to the injector.

NOTE

The Injector test gauge should not be subjected

to shock pressure. Keep the gauge valve open

only when reading pressure.

1.

Close gauge valve and work pump handle

several sharp strokes to dislodge any carbon or

dirt particles in nozzle cavities.

2.

Open gauge valve, work pump slowly, and

observe

nozzle

opening

pressure.

(Specification: 2050-2130 psi). If opening

pressure is not correct, remove nozzle from

nozzle holder and shim as required to obtain

2050-2130 psi. If shims are not available,

replace nozzle.

NOTE

It is desirable to have all injectors set as nearly

alike

as

possible

in

the

same

engine.

3.

Maintain a pressure of 2050-2130 psi and

watch for dribble from spray orifice, indicating a bad

seat; or "weeping" around cap nut, indicating a leak

between the holder and valve body lapped surfaces.

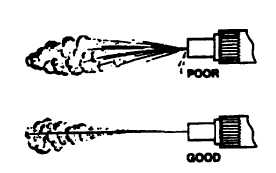

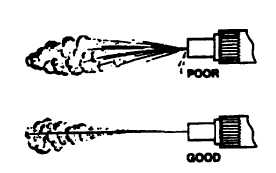

4.

Close

gauge

valve

and

observe

spray

characteristics while working the tester about

100 strokes per minute. "Flags," heavy ends,

deflected core, or a spray pattern that is not

symmetrical are undesirable. Repair or replace

faulty parts as necessary. A target 12" from the

nozzle end, with bullseye level with pintle will

show any deflection of spray pattern.

F-205

|