| |

TM 10-3930-671-24

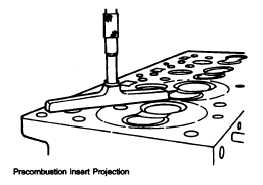

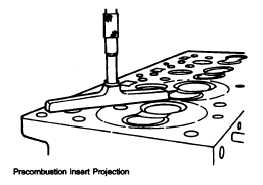

2.

Install precombustion chamber inserts, making

sure they are fully seated. Insert projection in

reference with cylinder head surface is flush to

.003" (0.076 mm) projection.

3.

Use

new

cylinder

head

gasket,

which

is

precoated, thus no cement is required.

4.

Using a chain hoist, lower the cylinder head

assembly evenly over the locator stud. Replace

the locator stud with the proper cylinder head

cap screw.

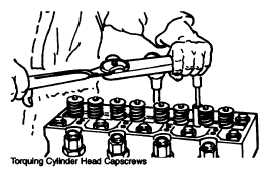

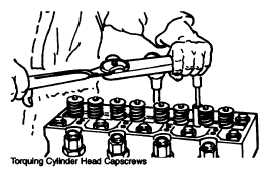

5.

Before installing any head cap screws in the

block, be sure the threads in the block and on

the cap screws have been properly cleaned.

Should these tapped holes need cleaning or

reconditioning, care should be taken to use the

proper tap.

Tap:

M 10 x 1.5 CLASS 6G

M 12 x 1.54 CLASS 6G 6.

6.

The cylinder head cap screws require no sealant

but should be installed with a very light coating

of engine oil or lubriplate to reduce friction and

insure proper clamp load and head cap screw

torque.

Tighten

with

torque

wrench

in

recommended sequence to the correct torque

shown in torque chart in Section 10, by going

over them two times before pulling them down to

the final torque specifications on the third round.

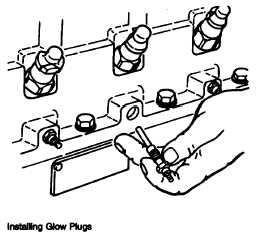

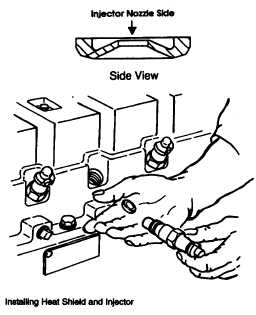

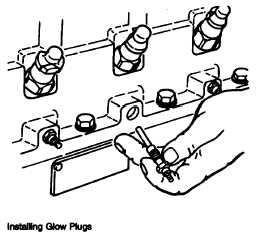

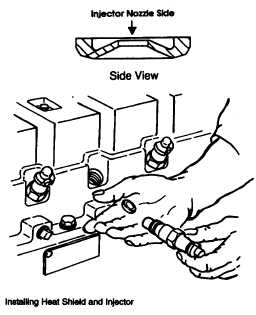

7.

Install the injectors and glow plugs at this point.

Having the injectors and glow plugs in now

eliminates the risk of dirt and foreign objects

falling into the cylinder.

NOTE

Always use new steel heat should

washers when installing injectors in

cylinder head.

F-187

|