| |

TM 10-3930-671-24

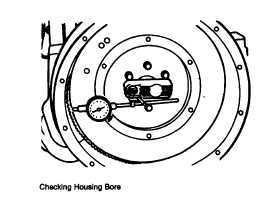

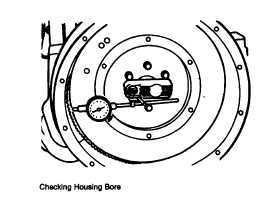

Re-locate the indicator to contact the housing bore and

check this in the same manner. The same runout limits

prevail.

REASSEMBLING ENGINE

In the foregoing, we have outlined procedures for

checking, repairing or replacing the many wearing parts

in the engine.

In most cases, the instructions have covered the

reassembly of parts or subassemblies made up of

several parts.

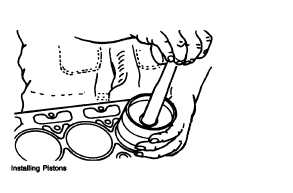

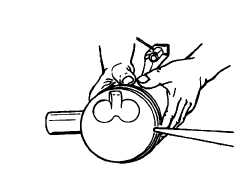

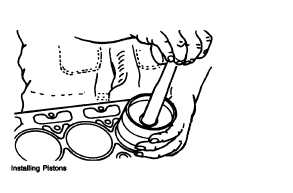

When reassembling pistons and connecting rods, use a

good ring compressor and oil the bores thoroughly. A

hammer handle may be used to bump the pistons out of

the ring compressor in-to the c linder bore.

NOTE

The pistons have offset piston pins.

Be sure to install pistons with notch

or arrow in top toward the front of the

engine.

Once more, we call attention to care demanded to

prevent connecting rods damaging the cylinder bore

finish and at the same time as they are assembled over

the crank pin, locate them carefully in order to protect the

bearing surfaces.

Always lubricate the bearings with clean engine oil when

assembling, and tighten them to the torque specified.

INSTALLING HEAD

1.

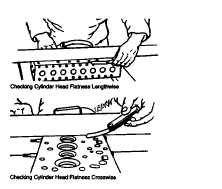

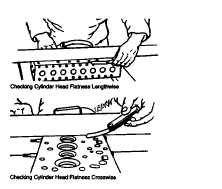

Make sure that gasket contact surfaces on the

head and block are clean, smooth and flat.

Check flatness with straight edge and feeler

gauge in three positions lengthwise and five

crosswise.

The

maximum

permissible

is

0.10mm (.004") low in the center lengthwise,

gradually decreasing towards the ends, or

0.076mm (.003") crosswise or in localized low

spots. If these limits are exceeded, replace the

cylinder head.

F-186

|