| |

TM 10-3930-671-24

9.

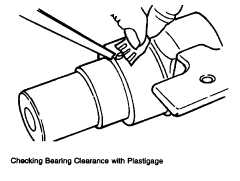

Check each bearing, one at a time, by using a

piece of Plastigage of a diameter specified to

check certain clearances.

By placing the Plastigage on the crankshaft bearing

surface and tightening the bearing and cap in place the

width of the Plastigage after crushing will determine the

bearing clearance.

CAUTION

When using Plastigage method DO

NOT TURN the crankshaft as that

would destroy the Plastigage.

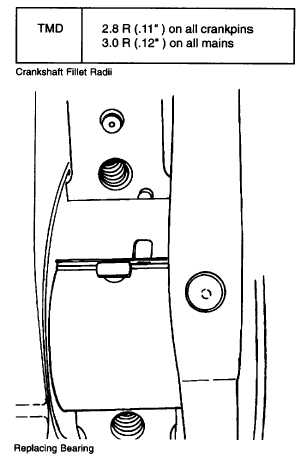

If crankshaft is scored, or worn enough so that new

bearings will not fit with the required clearance, it should

be removed and reground.

Standard crankshafts may be reground to decrease the

diameter a maximum of 1.0mm (.040").

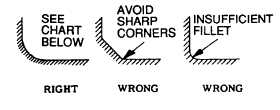

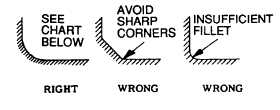

Before shaft is reground, it must be checked for

straightness and straightened if necessary to be within

0.05mm (.002") indicator reading. When reground, the

fillet radii must be within dimensional limits and must be

perfectly blended into thrust and bearing surfaces.

Crankshafts must be nitempered after regrinding.

CAMSHAFT

1.

Remove the screws holding the camshaft thrust

plate to the front of the cylinder block, which

makes it possible to pull the camshaft forward

out of the bearings.

2.

Measure the camshaft bearing journals and

bores. If clearance is equal to orgreaterthan the

amount indicated underwear limits, check the

diameter of the camshaft journals to determine

the next step. Excess wear at these positions

require replacement of the shaft.

3.

If the front camshaft journal bore becomes worn

beyond limits, there is a service camshaft

bushing available.

4.

Tappets can then be lifted out and lined up in

sequence, for installation in the same location

unless inspection shows that they require

replacement.

F-180

|