| |

TM 10-3930-671-24

Oil Piston and Rings

3.To install the balance of the rings, use a ring tool with

recess side up and place the ring in with the bottom

side up. Start with the lowest ring first.

a.

Position ring in the tool so the expanding

fingers will fully engage both ends.

b.

Apply pressure on handles so ring is

completely expanded. Pass the expanded

ring and tool recessed side down over the

piston to the proper groove.

Install Tapered Rings with “Top” Side Up

CAUTION

Some piston rings are taper faced. These are clearly

marked ’TOP" on the side to be up when assembled

on piston, and some rings have the top side marked

with a color band or a PIP mark. The pistons have

offset piston pins. Be sure to Install pistons with

notch or arrow In top toward the front of the engine.

4.When pistons are ready for installation in the cylinders,

oil generously. Compress rings carefully using a good

ring compressor and a light tap on the head of the

piston will allow the assembly to go into the cylinder

very easily. If any difficulty in tapping piston and ring

assembly into the cylinder is encountered, the

compressor should be removed and rings checked for

correct installation in the groove.

CRANKSHAFT & MAIN BEARINGS

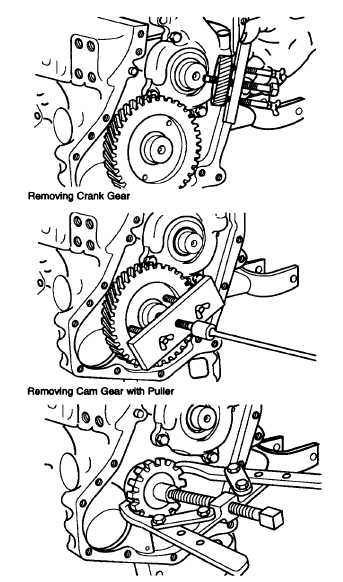

1. Using a puller, remove pulley from crankshaft.

2. Remove screws and remove gear cover.

3. Remove the crankshaft gear and woodruff keys.

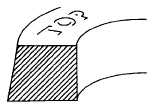

4. Using a puller, remove cam gear and injection pump

drive gears.

5. Remove the oil pump and key by removing cap

screws holding pump to front of the engine.

Removing Injection Pump Drive Gear

6.Remove each main bearing cap, one at a time, and

inspect the bearing and crankshaft journals. If there is

any indication of flaking out, scoring or actual wear -

they must be replaced.

F-178

|