| |

TM 10-3930-671-24

When the correct fit is obtained you must be able to

withdraw the feeler with a pull of 5-10 pounds (2.3-4.5

kg) on the scale, with the feeler inserted between the

piston and the cylinder mid-way between the piston pin

bosses where the diameter of the piston is the greatest.

Check the fit of the piston when it is approximately 2"

(50mm) down to the cylinder bore in an inverted position.

PISTON PINS

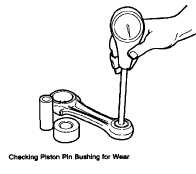

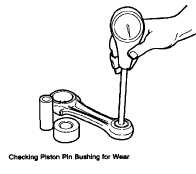

Check the bushing in the upper end of the connecting

rod for wear. If worn and you are using the original

pistons, an oversize piston pin may be obtained in .003

or .005" (0.08 or 0.13mm) oversize.

The piston pin hole in the piston and the bushing in the

connecting rod may be honed to increase their diameter

to obtain the desired fit as shown in our Limits and

Clearance Chart.

Note that, while the chart specifies a light press of the pin

in the piston, there is a definite clearance of the piston

pin in the connecting rod.

CONNECTING RODS

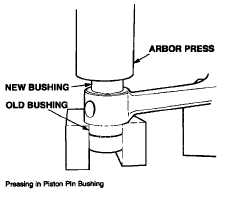

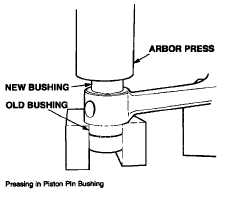

Replace the bushing in the connecting rod if new pistons

are used. Using the arbor press, press out the old

bushing and press in the new one making sure the oil

supply holes line up-after which the bushing must be

honed to obtain the correct fit of the pin in the bushing as

shown on Limits and Clearance Chart. If there is an

excess of stock in the piston pin bushing, it may be

reamed first, then honed. In any event, the final

operation should be done with a hone to obtain the

desired fit with better than 75% bearing area contact on

the pin.

PISTON & CONNECTING ROD ASSEMBLY

1.

Assemble the pistons on the connecting rod.

Heating

them

in

hot

water

will

facilitate

assembly. When heated, the piston pin will

enter the piston very easily and can be tapped

through the connecting rod and into place

without distorting the piston. The snap rings

must be assembled in the grooves, making sure

they are fully seated in place.

2.

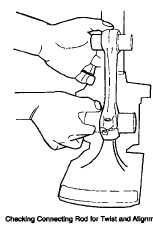

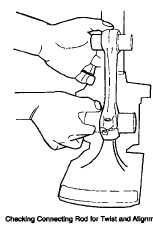

The piston pin hole in the connecting rod must

be parallel to and in plane with, the large bore in

the bearing end of the connecting rod.

F-176

|