| |

TM 10-3930-671-24

Several good makes of ridge reamers are available

which will ream the top of the bore in direct relation to the

worn area so that, should the worn area be off-center

slightly, there will be no partial ridge remaining.

2.

Drain the crankcase and remove the oil pan.

3.

Remove the cap screws holding the connecting

rod caps to the rod. Keep the cap and bolts in

numerical order so that when the pistons and

rods are removed from the engine, the cap can

be reassembled and kept with its mating part.

4.

Push the pistons and connecting rods up

through the top of the cylinder, carrying with

them all the carbon and metal chips left from the

cleaning and ridge reaming operation. When

doing this, every precaution must be taken to

prevent damage to cylinder bores by the sharp

comers and rough edges of the connecting rods.

5.

It is important to remove the glaze on the

cylinder bores by using a cylinder hone, with an

adjustable stone tension, in order to assure

quick seating of the new piston rings. If the

cylinder glaze is not removed, you will have no

assurance as to when the rings will begin to

function properly and control the oil; this is

especially true when chrome rings are used.

The

following

step-by-step

procedure

Is

recommended:

a.

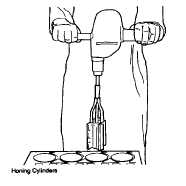

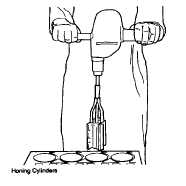

To get the correct crosshatch pattern with a

cylinder hone, use a top quality electric drill

with a speed of 500 R.P.M. or less and 280

grit stones.

b.

Cover the entire crankshaft with a clean,

slightly oily cloth to prevent abrasives and

dirt from getting on the crankshaft.

c.

Remove the excess carbon deposits from

the top of the cylinder wall before beginning

the glaze breaking operation (this is to

prevent loading the stones).

d.

Insert hone in cylinder and expand to

cylinder wall with slight tension. Using a

clean brush, wet cylinder wall and stones

with kerosene. Use a hand drill and surface

hone cylinder with a rapid up and down

motion to produce a good crosshatch

pattern. Apply kerosene continuously and

increase tension on hone adjustment until a

good pattern and finish is obtained. A

smooth, bright finish of 10 to 15 micro

inches (0.25 0.38 micro meters) is desired.

The honing operation will produce a sharp edge at the

bottom of the bores. Upon completion of the honing

operation, remove this sharp edge with a piece of

number 500 emery cloth. If this edge is not removed, it

can cause shaving of the piston skirts.

Removing Sharp Edge After Honing

e.

Clean the loose abrasives from the stones

by using kerosene and a wire brush.

IMPORTANT: Stones must be used wet. Keep

applying kerosene during honing to prevent stones

from drying out and causing an incorrect honing

pattern.

f.

The most desirable cylinder finish is10-1 5

micro inches (0.25 -0.38 micro meters); with

this finish, the depressions in the surface

tend to keep a supply of lubrication between

the mating parts: this finish can be obtained

by using 280 grit stones on the hone.

F-174

|