| |

TM 10-3930-671-24

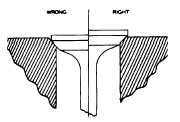

Valve Position in Head

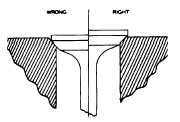

"A poor valve grinding job cannot be corrected by

valve lapping."

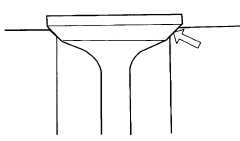

For example, after the valve has been hand lapped, it

would look like this when cold. The thin line visible here

shows where the valve lapped into its seat. Keep in

mind that the engine is now at rest and cold.

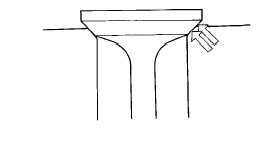

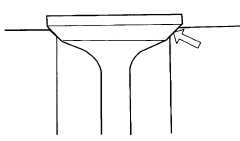

This illustration shows the same valve only now it has

reached normal operating temperature. Notice that the

lapped area of the valve and the seat no longer match

each other. This is perfectly normal due to expansion of

the valve. Now you can see that the effects of the

lapping job are lost completely. So remember...do not

lap valves in after grinding.

5.

Coat the valve stem with a light film of engine oil.

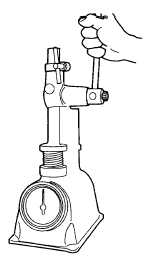

VALVE SPRINGS

1.

Check all valve springs on a spring tester to

make sure they meet specifications regarding

weight and length.

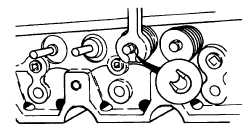

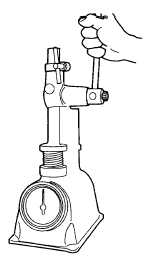

Valve Spring Tester

Springs, when compressed to the "valve open" or “valve

closed" length, must fall within the specifications shown

on the Limits and Clearance chart when new, and must

not show more than 10% loss to re-use.

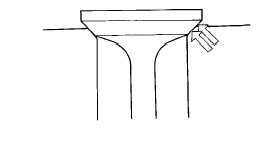

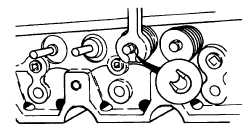

Valve Assembly

F-172

|