| |

TM 10-3930-671-24

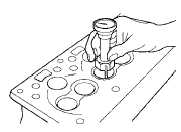

Grinding Valve Seat

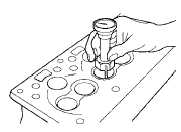

Indicating Valve Seat

VALVES

1.

Inspect valves for condition and replace any that

are "necked", cracked or burned, also any of

which valve stems are bent or worn more than

.002" 0.05mm over the maximum allowable

limits. Reface or replace all valves.

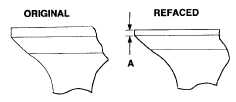

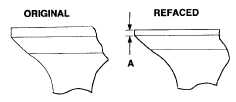

IF AREA "A" IS LESS THAN 50% OF ORIGINAL,

DISCARD VALVE

Allowable Head Thickness of Refaced Valves

2.

All

valves

having

less

than

50%

margin

thickness (outer edge of valve head) after

refacing has been completed must be replaced.

To check this dimension, compare the refaced

valve with a new valve.

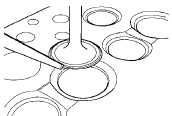

Checking Valve Face in "V" Blocks

3.

Check all refaced or new valves in V-blocks with

indicator to determine if the contact face is true

with the stem within .002" (0.05mm). If not,

repeat the refacing operation.

4.

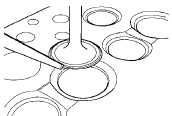

After the valves and seats have been refaced

and reground, coat the seat lightly with Prussian

blue and drop the valve into position, oscillating it

slightly to transfer the blue pattern to the valve

face. This should show a contact width of 1/16’

to 3/32" (1.62 to 3.2mm) and should fall well

within the width of the valve face, leaving at least

1/64" (0.4mm) on either side where the blue

does not show. If the contact is over 3/32"

(3.2mm) wide, the seat in the head may be

narrowed by using a 150 stone to reduce the

outside diameter or using a 6(0 or 750 stone to

increase the inside diameter.

Checking for Proper Valve Seating

Never allow valves to set down Inside the seat.

After

the

narrowed-down

seat

is

brought

within

specifications, the seat should be retouched lightly with

the original stone to remove burrs or feathered edge.

F-171

|