| |

TM 10-3930-671-24

Cleaning Combustion Pocket

Clean and insert combustion pocket. Inspect carefully

for cracks.

4.

Remove all carbon from combustion areas using

scraper and wire brush.

5.

Clean the cylinder head thoroughly with a solvent

or degreasing solution and blow it off with air

pressure. Inspect carefully for cracks.

VALVE GUIDES

1.

Clean the valve stem guides, removing lacquer

or other deposits. Do not use tools that remove

metal.

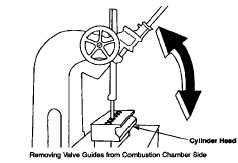

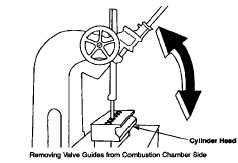

2.

Check guides for wear by using a telescope

gauge and 1" micrometer. Replace all guides

that are worn bell-mouthed or have increased

.0015" (0.038mm) in diameter. See Limits and

Clearance

Section

for

maximum

diameter

permissible to determine actual amount it has

increased. Remove all valve guides when

necessary by pressing them out from the

combustion chamber side.

3.

Replace worn guides as required by pressing in

new guides to the correct depth as given in the

Valve Guide Data figure on the following page.

CAUTION

When replacing guides do not ream

since these are all pre-reamed before

being

ferrox

coated-any

further

reaming will remove the coating and

damage guides.

VALVE SEAT INSERTS (IF SUPPLIED)

1.

The exhaust valve seat insert is held in place by

a shrink fit.

Inspect all exhaust valve inserts in the head and

replace any that are loose, cracked or other wise

damaged. Use puller for removing faulty insert.

2.

When required to replace with new insert, clean

and counterbore for .010" (0.25mm) larger insert

using counterbore tool with correct fitting pilot.

When machining the counterbore, be sure to go

deep enough with the tool to clean up the bottom

so that the insert will have full contact to carry

away the heat.

Continental does not recommend installing new

inserts having the same outside diameter as the

one removed.

New insert installation must have a press fit.

Chill insert in container with dry ice for 20

minutes before assembling.

Insert may then be installed in the counterbore

using a piloted driver and arbor press, without

the possibility of shearing the side walls. This

assures it being seated firmly on the bottom of

the counterbore.

3.

Grind the intake and exhaust valve seats in the

head in accordance with instructions in the Valve

Guide Data figure. Before removing the arbor,

indicate the seat. Total indicator reading of the

runout must not be more than .002" (0.05mm) .

Use a pilot having a solid stem with a long taper,

as all valve seats must be ground concentric and

square with either new or worn valve stem guide

holes.

F-169

|