| |

TM 10-3930-671-24

11.

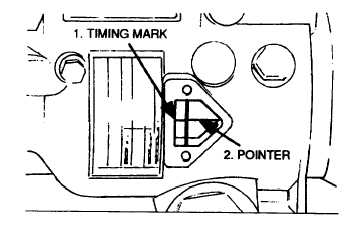

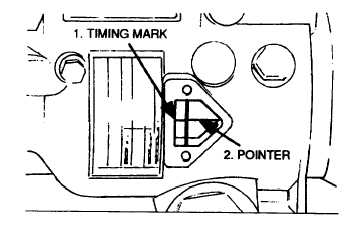

Turn the injection pump gear until the internal

timing marks are lined up (See Below).

Turn the injection pump gear until timing mark is aligned

with the pointer

12.

Guide the injection pump into position and install

the three long

M10

mounting

bolts,

lock

washers, and nuts that secure the adaptor

mounting plate to the engine. Torque the M10

bolts to 25-30 lb-ft (34-40 N•m).

13.

Inspect the internal timing marks again. The two

marks should look like one unbroken horizontal

line. If not, you must judge as to whether the

pump gear is one tooth or more out of time or if

a minor rotation of the injection pump body will

align the marks. If the marks are far apart,

repeat step 12 because the pump gear is

probably out of time. If the marks are very close

together, rotate the body of the injection pump

one way or the other until the marks line up.

14.

Torque the three M8 bolts that fasten the

injection pump to the adaptor plate to 15-18 lb-ft

(20-24 N•m).

15.

Recheck the timing marks after eliminating the

backlash and play that may be in the timing gear

train. This is done by rotating the crank pulley

counterclockwise approximately 1/4 turn (viewed

from the front). Then, rotate the crank pulley

clockwise until it is back to the prescribed timing

position. Check the internal timing marks once

again and adjust if needed.

16.

Install the timing hole cover and gasket onto the

injection pump housing.

NOTE

Leave any two of the fuel line nuts

loose at the nozzles for Bleeding the

Fuel System.

17.

Install the high-pressure fuel lines and torque the

fuel line nuts to 20-25 lb-ft (27-34 N•m).

18.

Reconnect all electrical wires; linkage rods; low-

pressure fuel lines, etc.

19.

Bleed the fuel system.

F-156

|