| |

TM 10-3930-671-24

Be prepared, with a container, to catch the fuel as it

comes out of the open line. A steady solid stream of fuel

indicates that the fuel pump is probably okay for

continued use. A broken stream with bubbles and

dribbles or no fuel at all indicates the fuel pump is

probably bad or that there are restrictions somewhere in

the fuel circuit. There could also be an air leak in the fuel

pickup line on the suction side of the pump causing the

pump to cavitate.

If restrictions are suspected in the fuel circuit, they are

most likely found to be either plugged fuel filters or trash

on the inlet side of the electric fuel pump.

BLEEDING THE FUEL SYSTEM

Bleeding is necessary on initial installation of the fuel

injection system after any subsequent removal and if the

system should be drained after having run out of fuel.

NOTE

Electrical equipment such as starters

should be shielded with non-conductive

material during the bleeding process to

prevent damage from fuel entry. Also, be

certain that all transmissions, gearboxes,

hydraulic control, etc., are in a neutral

position before attempting to crank the

engine. If a wheel vehicle is involved, be

certain that the wheels are “chocked”

and the parking brake is set.

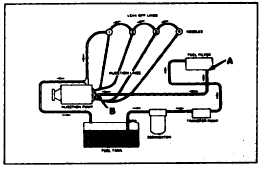

STANADYNE Fuel System

1.

Turn the ignition switch to the ’ON position.

2.

Loosen the filter outlet connection (A), or the fuel

injection pump inlet connection (B)whichever is

the higher, and allow fuel to flow until free of air.

Tighten the connection.

NOTE

If connection (A) is inaccessible due to

the

type

of

filter

In

use,

loosen

connection (B).

Typical STANADYNE Fuel System Schematic’

3.

Loosen any two injector high-pressure pipe nuts

at the injector end. Set the accelerator to the

fully open position and with the ignition switch

"ON," crank the engine until fuel free from air

flows. Tighten the line nuts.

4.

Start the engine.

FUEL FILTERS

Clean fuel is a must in diesel operation. Extreme

conditions may require additional filters to provide longer

filter change periods--when clean fuel is not available.

Continental diesels are normally equipped with the filter

installed between the fuel injection pump and the transfer

pump outlet-so the filter is on the pressure side of the

transfer pump.

The period for changing the element will largely depend

upon the quality and condition of the fuel available.

Under normal conditions, the element should be

renewed every 400 hours. This period should be

decreased if unavoidable contamination of the fuel is

experienced.

NOTE

Electrical equipment such as staners

should be shielded with non-conduction

material during filter replacing and

priming to prevent fuel entry.

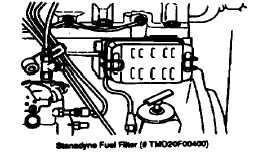

STANADYNE FUEL FILTER

NOTE

This fuel filter is not a water separator. If

water contamination is anticipated, an

additional primary fuel filter and water

separator should be installed before the

fuel transfer pump.

No attempt should be made to clean this type element.

It should be replaced at the regularly scheduled periodic

maintenance interval or if there is reason to believe that it

is plugged. To replace the metal canister element,

simply release the two spring clamps and pull the old

element off the filter bracket. Lube the new element

grommets with clean diesel fuel and push into place.

Snap the spring clamps into position and bleed the fuel

system.

F-152

|