| |

TM 10-3930-671-24

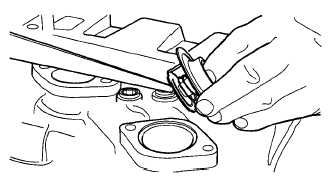

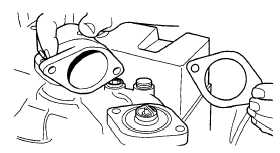

When replacing the thermostat in the water header be

sure the counterbore is clean.

When installing a new thermostat in the water header

make sure that the temperature sensing unit goes in first

or faces toward the cylinder head.

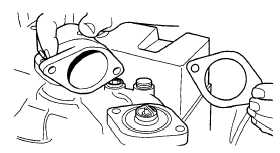

Assemble new water outlet elbow mounting gasket

Thermostat flange must seat in counter-bore with gas ket

sealing contact between it and the outlet elbow.

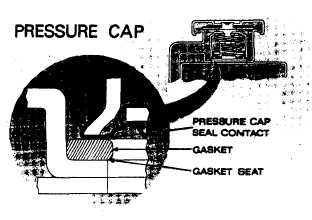

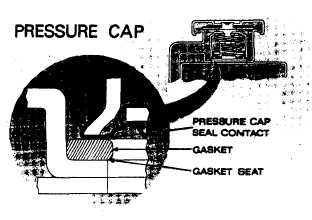

RADIATOR PRESSURE CAP

If the coolant Is hot or if the engine

has

been

running,

loosen

the

pressure cap to the first stop and let

the pressure out of the cooling

system before removing the radiator

cap.

Many operations use a pressure cap on the radiator to

prevent overflow loss of coolant during normal operation.

This spring-loaded valve in the cap closes the outlet to

the overflow pipe of the radiator and thus seals the

system, so that pressure developing within the system

raises the boiling point of the coolant and allows higher

temperatures without overflow loss from boiling. Most

pressure valves open at 0.3 or 1.0 Bar (4 1/2 or 15 PSI),

allowing steam and water to pass out the overflow pipe,

however, the boiling point of the coolant at this pressure

is 224°F (107'C) or 248OF (120'C) at sea level. When a

pressure cap is used an air tight cooling system is

necessary with particular attention to tight connections

and a radiator designed to withstand the extra pressure.

FAN BELT TENSION

When tightening fan belts, loosen the alternator adjusting

bolts and pull out on the alternator by hand until the belt

is just snug. Under no circumstances should a pry bar

be used on the alternator to obtain fan belt tension or

damage to the bearings will result.

When adjusted correctly the fan belt deflection on the

long side should not exceed 1/2" (13mm) .

F-148

|