| |

TM 10-3930-671-24

system ineffective to properly maintain normal operating

temperatures. The appearance of rust in the radiator or

coolant is a warning that the corrosive inhibitor has host

its effectiveness and should be cleaned before adding

fresh coolant.

Dependable cleaning compounds should be used.

Follow the procedure recommended by the supplier.

This is of prime importance because different cleaners

vary in concentration and chemical compositions. After

cleaning and flushing, the system should be filled with an

approved anti-freeze compound containing a rust and

corrosion inhibitor.

REVERSE FLOW FLUSHING

Whenever a cooling system is badly rustclogged as

indicated by overflow loss or abnormally high operating

temperatures, corrective

cleaning

by

reverse

flow

flushing will most effectively remove the heavy deposits

of sludge, rust and scale. The reverse flow flushing

should be performed immediately after draining the

cleaning solution. It is advisable to flush the radiator first,

allowing the engine to cool as much as possible.

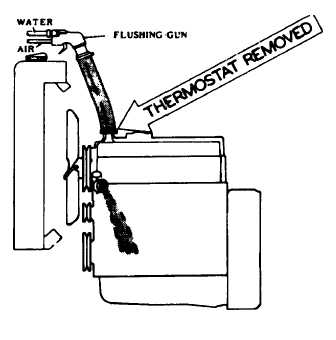

Reverse flush the radiator, as follows:

1.

Discontent the hoses at the engine.

2.

Put radiator cap on tight.

3.

Clamp the flushing gun in the lower hose with a

hose clamp.

4.

Turn on the water and let it fill the radiator.

5.

Apply air pressure gradually, to avoid radiator

damage.

6.

Shut off the air, again fill the radiator with water

and apply air pressure. Repeat until the flushing

stream runs out clear.

7.

Clean and inspect radiator cap.

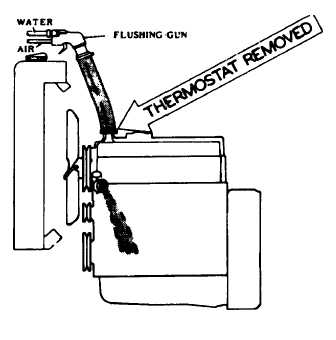

To reverse, flush the engine water jacket:

1.

Remove the thermostat.

2.

Clamp the flushing gun in the upper hose.

3.

Partly close the water pump opening to fill the

engine jacket with water before applying the air.

4.

Follow the same procedure outlined above for

the radiator by alternately filling the water jacket

with water and blowing it out with air 5.5 Bar (80

PSI) until the flushing stream is clear.

TESTING THERMOSTAT

Remove the water outlet elbow. Before testing, clean

and examine the thermostat. If the valve can be pulled

or pushed off its seat with only a slight effort when cold

or it does not seat properly, the unit is defective and

should be replaced.

Thermostat operation can be checked In the following

method:

1.

Hang thermostat by its frame in a container of

water so that it does not touch the bottom.

2.

Heat the water slowly and check temperature

with a thermometer.

3.

If

the

valve

does

not

start

to

open

at

temperatures of 180 - 200"F 81- 930C or it

opens well before the 180°F (81 C) point Is

reached, the thermostat should be replaced.

F-147

|