| |

TM 10-3930-671-24

There are instances where this corrosive element has

eaten holes through cast iron parts such as water pump

impellers and bodies. This condition is caused by

electrolysis taking place in the parts involved. Where

these

conditions

exist,

water

filters

should

be

incorporated

in

the

assembly

to

remove

these

troublesome elements and off-set the electrolytic action.

EFFECT OF ALTITUDE ON COOLING

Water boils at 212°F (100°C) under atmospheric

pressure at sea level. This pressure becomes less at

higher altitudes and the reduced pressure causes water

and other liquids to boil at a lower temperature.

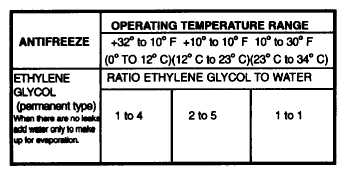

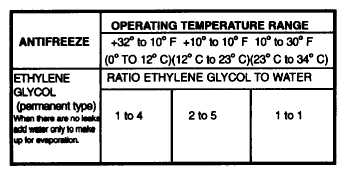

ANTI-FREEZES

Water freezes at 32°F (0°C), forming solid ice and

expanding

about

9%

in

volume-which

causes

tremendous pressure and serious damage when allowed

to freeze inside the cooling system. When operating

temperatures are below 32°F (0°C), an anti-freeze liquid

must be added which will lower the freezing point to a

safe margin below the anticipated temperature of outside

air. Permanent anti-freeze will also raise the boiling

temperature of the coolant. The correct proportion of

anti-freeze is also important when the engine is to be

operated under high ambient temperature conditions.

CORROSION INHIBITORS

Corrosion inhibitors can cause damage

to the eyes or skin. n contact is made,

immediately wash skin with water. For

the eyes, Immediately flush the eyes with

water for several minutes. In either

event, seek prompt medical attention.

Water forms rust due to its natural tendency to combine

chemically with iron and air in the system. Rust inhibitors

for water are inexpensive, simple to use and make

cleaning and flushing necessary only after long periods

of operation.

The addition of a corrosion inhibitor is not necessary if an

anti-freeze containing a rust inhibitor is used.

RADIATOR

The radiator or heat exchanger consists of a series of

metal tubes through which the coolant is circulated. In

standard radiator design fins are connected to the metal

tubes to give an extended surface through which heat

can be dissipated. It is important that these tubes be

kept clean on the inside and the fins free of dirt on the

outside so the maximum heat transfer can take place in

the radiator.

Blowing out between the fins of the radiator, using

compressed air, in a direction opposite to that of the fan

circulated air, will serve to keep the cooling surfaces of

the core free of dirt and other particles. Operating

conditions will determine the frequency of this service.

Every 500 hours of operation the radiator and cooling

system should be well cleaned and flushed with clean

water.

Radiator Coolant Inlet

Wherever possible, only soft clean water should be used

in the cooling system. Hard water will cause scale to

form in the radiator and the engine water jackets and

cause poor heat transfer. Where the use of hard water

cannot be avoided an approved water softener can be

used.

CLEANING COOLING SYSTEM

Deposits of sludge, scale and rust on the cooling

surfaces prevent normal heat transfer from the metal

surfaces to the coolant and, in time, render the cooling

F-146

|