| |

TM 10-3930-671-24

e)

Check engine oil to see if it contains

coolant.

f)

Check

that

radiator

cap

has

correct

pressure rating. Replace if incorrect.

g)

Pressure test the radiator cap. Replace if

faulty.

h)

Pressure test the radiator and cooling

system. Repair any leaks or blockage.

i)

Test the engine thermostat. Replace as

needed.

Cooling System Inspection

WARNING

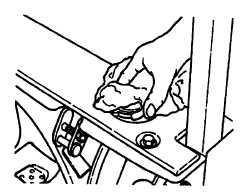

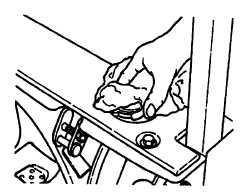

Use extreme care when removing the

cap from the radiator. It is good safety

practice to use a shop cloth to cover

the radiator cap while it is being

removed. Wrap the cloth around the

cap and turn cap slowly to the first

stop. Step back while the pressure is

released from the system. When you

are sure all of the pressure has been

released, press down on the cap with

the cloth in place, turn, and remove the

cap. Stand clear of the radiator

opening; hot coolant may splash out.

Failure to follow these instructions

could result in serious personal injury

from hot coolant or steam blowout

and/or damage to the cooling system or

engine.

NOTE

A coolant solution containing 50%

ethylene

glycol

provides

freezing

protection to -34°F (-37°C).

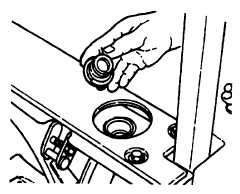

1.

Remove the radiator cap.

2.

Inspect the condition of the coolant. Look for

excessive contamination, rust, or oiliness, and

gummy deposits in the coolant solution. The

coolant should have a clean appearance.

3.

Check the PM time Interval, or the condition of

the coolant, to determine if it needs to be

changed (drained and replaced).

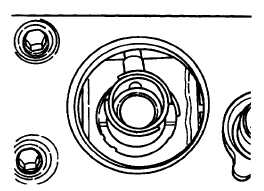

4.

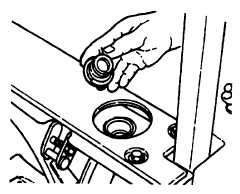

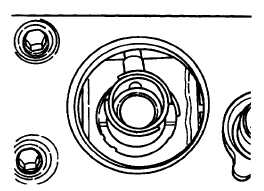

Inspect the radiator cap. Check condition of

upper and lower rubber seals (with overflow

reservoir, cap has two seals). Check the seal

holder and spring for correct movement and

operation. The rubber seal face should be clean

and not damaged. Look for nicks and cracks in

the seals. Replace the cap if it is defective.

5.

Be sure the radiator cap has the correct

pressure rating. System Pressure (Radiator

Cap) 14 psi, nominal.

Refer to Section 2.1, Service Specifications, Cooling

System.

6.

Inspect the radiator cap sealing surfaces located

in the radiator filler neck. Look for nicks, deep

scratches, or damage which may cause radiator

cap leakage.

7.

Inspect the overflow pipe and tubing for clogging

damage and wear. Clean the overflow pipe.

Remove any contaminants that can cause

restriction. Replace the tubing if it is faulty.

8.

Inspect and clean the overflow reservoir, as

needed.

F-95

|