| |

TM 10-3930-671-24

1.

Put directional control level in FORWARD (or

REVERSE), as applicable, depending upon truck

position to barrier.

2.

To test all clutch assemblies in the transmission,

check

stall

speeds

and

vacuum

with

transmission in forward and reverse.

3.

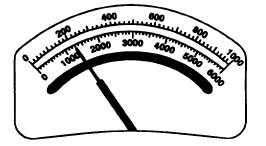

Check stall speed at full throttle. Slowly push the

accelerator pedal to its maximum travel (fully

down) position and hold while doing test.

Stall tests should be a part of all engine tune-ups and

must be carefully conducted and analyzed to pinpoint

specific problems.

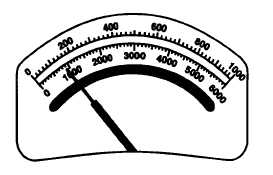

Stall tests must include RPM and hydraulic pressure

measurements to accurately diagnose specific problem

areas.

Engine speed checks with engine under load are made

to also determine whether major components or

systems-other than the engine-are causing problems.

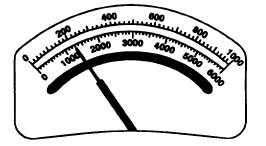

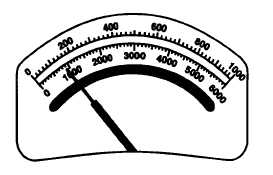

Full Throttle Stall Speed Chart

TMD 27 Engine

2100 rpm, nominal

Range: 2000 2500 rpm

Analysis of Stall Test

NOTE

•

If stall speed is low, do not automatically

blame the torque converter. Carefully

check engine condition. Frequently an

obstruction, e.g. carbon plugging, in the air

intake or exhaust system is the problem.

•

When high stall speed is found, perform

transmission pressure tests (see following)

to help isolate the problem area.

1. Operation at nominal stall speed is an indication

that:

a)

Engine performance is good (correct).

b)

Torque converter is operating correctly.

c)

Transmission clutch packs are operating

correctly (not slipping).

2. Below normal stall rpm is typically 1500 - 1800

rpm. Low stall rpm is an indication that the:

a)

Engine performance is faulty (needs tune-

up or repair).

b)

Hydraulic pump is defective or return line

is blocked. Repeat hydraulic bypass test.

c)

Transmission and torque converter are in

satisfactory condition (performance is

correct).

F-90

|