| |

TM 10-3930-671-24

Critical Fastener Torque Checks (Cont’d)

NOTE

The following items illustrate procedures for critical

torque checks for selected items.

Transaxle Mounting

Mounting bolts, nuts, washers, and threaded holes are

not to be lubricated. Impact wrenches to be used only to

snug-up the fasteners. Torque measuring wrench must

be used to obtain final torque values.

NOTE

Also check drive wheel bearings when wheels are

blocked up. See Section 3.2.

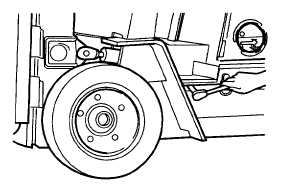

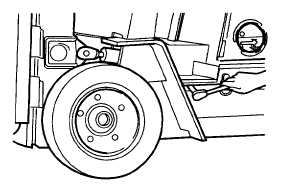

1.

Remove the frame side compartment doors from

each side of the truck.

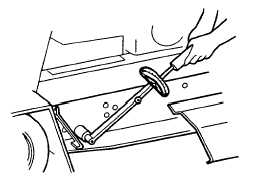

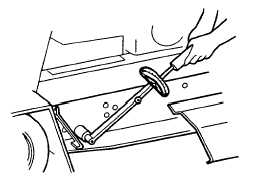

2.

Check transaxle mounting bolts and nuts for

correct torque. Tighten each bolt to torque spec:

400-440 Ib-ft (542-597 N•m).

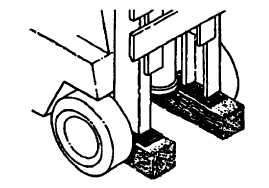

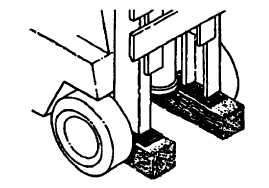

1. Raise drive wheels off the floor. With upright in

full back tilt, place wood blocking beneath rails or

upright.

2. Check the transaxle mounting bolts and nuts for

correct torque.

3. After checking upright mounting as noted below,

install drive wheels.

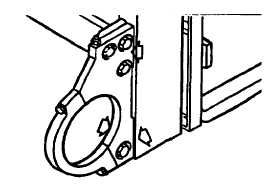

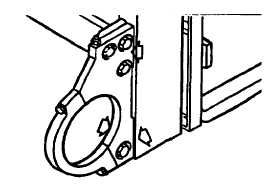

Upright Mounting

1. Check the upright trunnion bearings for wear.

Check the trunnion brackets for cracks or

damage.

2. Check the upright mounting bracket bolts. Be

sure no bolts are missing. Tighten each bolt to

correct torque spec: 273-302 Ib-ft (370-410

N•m).

3. Check tilt cylinder mounting and attachment

fasteners for safe installation. Tighten tilt cylinder

yoke clamp bolts to torque spec: 120-140 Ib-ft

(163-190 Nom).

4. Check and tighten the load backrest extension

mounting bolts to torque spec: 177-199 Ib-ft

(240-270 N•m).

F-57

|