| |

TM 10-3930-671-24

Air Cleaning

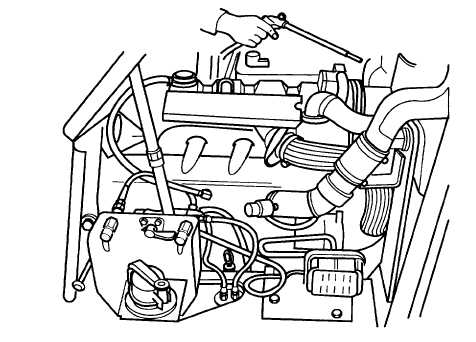

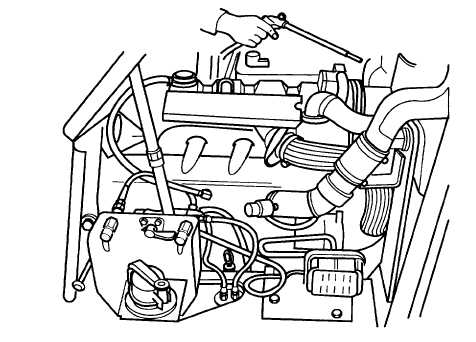

Typical View Showing Secondary Air Cleaning Procedure (Blowing From Engine Side).

Wear suitable eye protection and protective clothing or

injury could result.

NOTE

Use care when air cleaning radiator. Air pressure may

bend radiator fins.

Always maintain a lift truck in clean condition. Do not

allow dirt, dust, lint, or other contaminants to accumulate

on the truck. Keep the truck free from leaking oil and

grease. Wipe up all oil spills. Keep the controls and

floorboards clean, dry, and safe. A clean truck makes it

easier to see leakage and loose, missing, or damaged

parts. A clean truck will run cooler.

The environment in which a lift truck operates will

determine how often and to what extent cleaning is

necessary. The radiator, especially, may require daily air

cleaning to ensure correct cooling. If air pressure does

not remove heavy deposits of grease, oil, etc., it may be

necessary to use steam or liquid spray cleaner.

1.

Lift trucks should be aircleaned at every PM

interval, and otherwise as often as required.

2.

Air cleaning should be done using an air hose

with special adapter or extension having a

control valve and nozzle to direct the air properly.

3.

Use clean, dry, low-pressure compressed air;

restrict air pressure to 100 psi (690 kPa),

maximum.

Refer to Paragraph 5-4 for additional information on the

use of air nozzles and air cleaning procedures.

4. Air clean the:

a)

Radiator, from both sides: first from

counterweight side (to loosen and clean

away dirt opposite of fan air flow), then

blow away loosened dirt and clean radiator

from engine side.

b)

Engine and accessories.

c)

Driveline,

transaxle,

and

related

components.

d)

Steer axle and steer cylinder.

e)

Upright assembly.

f)

Tilt cylinders.

g)

Hydraulic control valve.

F-55

|