| |

TM 10-3930-671-24

Hydraulic Sump Fluid Level Check

Correct fluid level is important for proper hydraulic

system operation:

•

Low fluid level can cause pump damage.

•

Overfill can cause loss of fluid or lift

system malfunction.

•

Because of the expansion of fluid as its

temperature rises, it is preferable to check

the fluid level at operating temperature

(after approximately 30 minutes of truck

operation).

1.

Check the hydraulic sump tank fluid level daily.

2.

To check fluid level, park truck on a level surface

and apply the parking brake. Put upright in a

vertical position and lower fork carriage fully

down.

3.

Pull the dipstick out, wipe it with a clean wiper,

and reinsert it fully into the dipstick tube.

Remove the dipstick and check the oil level.

4.

Keep the oil level above the LOW mark on the

dipstick by adding recommended hydraulic fluid

only as required. DO NOT OVERFILL.

5.

Check the PM time interval (operating hours) or

the condition of the hydraulic fluid (age, color,

clarity, contamination, etc.) to determine if it

needs to be changed. Change (replace) the oil,

as necessary.

Refer to Section 2.1, Service Specifications, for hydraulic

oil specifications.

Hydraulic Fluid & Filter Change

It is recommended to:

•

Drain and replace the hydraulic sump fluid

every 2000 operating hours, or sooner, as

required.

•

Replace the hydraulic oil filter at every oil

change, or every 500 hours, whichever

occurs sooner.

•

Replace the sump tank breather/fill cap

every 500 operating hours, or as required.

There is no drain plug in the hydraulic sump tank. The

hydraulic fluid can be changed by one of the following

methods:

1.

Removal of the hydraulic sump tank cover

assembly and pumping the fluid out by suction

using a separate pump and hose.

2.

By connecting a quick-disconnect coupling to the

test port and pumping the fluid out using the

truck hydraulic system. This method may be

used most easily and satisfactorily for routine

changes of the fluid.

Refer to Section 10. 1, Main hydraulic System

Maintenance, for additional information.

Hydraulic Oil Filter

Remove and replace the hydraulic system fluid filter per

recommended PM schedule, or as may be required by

truck operating conditions and usage.

Refer to Section 10. 1, Main Hydraulic System

Maintenance, for additional information.

Sump Tank Breather Maintenance

1.

Remove the sump tank breather/fill cap and

inspect for excessive (obvious) contamination

and damage.

2.

Replace the breather/fill cap, per recommended

PM schedule, or as required by operating

conditions.

Refer to Section 10.1, Main Hydraulic System

Maintenance, for additional information.

Access To the Transaxle

Transaxle Fluid

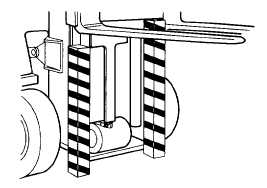

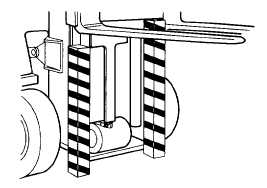

An upright or carriage can move unexpectedly. Chain or

block the carriage and each rail. FAILURE TO FOLLOW

THIS WARNING CAN RESULT IN SERIOUS INJURY

NOTE

If you are unfamiliar with this procedure, please refer to

Section

3.3,

Machine

Jacking

and

Blocking,

for

information on blocking the upright in raised position.

The best method to use for reaching the transaxle

checkpoints (oil level/filler plug and drain plugs) is

dependent upon the style of upright, carriage, and

attachments on your truck. One method is to raise the

upright carriage to provide easier access to the transaxle

from the front. See illustration.

Apply the parking brake and block the wheels. Be sure to

put blocking under the carriage and upright rails.

F-52

|