| |

TM 10-3930-671-24

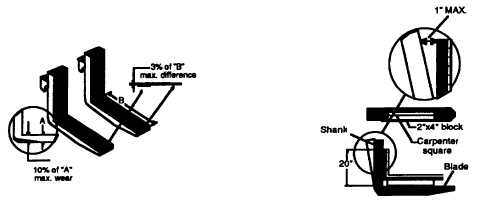

Forks

NOTE

•

If the fork blade at the heel is worn down

by more than 10%, the load capacity is

reduced and the fork must be replaced.

•

If the fork blades are obviously bent or

damaged, have them inspected by a

trained maintenance person.

1. Inspect the load forks for cracks, breaks,

bending, and wear. Move the forks together

side-by-side. The fork top surfaces should be

level and even with each other. The height

difference between both fork tops should be no

more than 3% of the fork length. Replace bent

forks.

2. At each PM interval, an inspection of the forks

must be made to check for wear. Check the

amount of wear at the heel of the fork. See

Table 1 below.

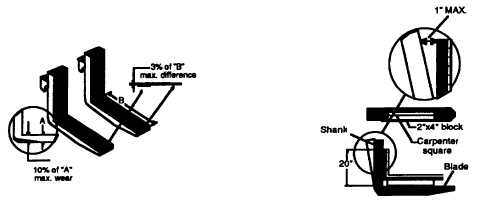

3. Inspect the forks for twists and bends.

To Check - Put a 2' thick metal block, at least 4" wide by

24” long, on the blade of the fork with the 4" surface

against the blade.

Put a 24” carpenter square on the top of the block and

against the shank.

Check the fork 20” above the blade to be sure it is not

bent more than 1-inch maximum.

Table 1. Fork Wear Chart

NOTE

The % capacity reductions are based upon wear only. Other factors such as cracks, cuts,

holes, etc., may further reduce the capacity of the fork

Allowable wear of fork thickness at heel of fork:

10% Wear:

Forks must be scheduled for replacement. With 10% wear, the forks are

adequate for only approximately 80% of rated capacity. Forks may be

used only until replacements are available.

20% Wear:

Forks are unsafe and must be removed from service immediately.

NEW

REPLACE

SAFETY HAZARD

Standard Fork

Nominal 10% Wear

Nominal 20% Wear

Thickness, Inches

Thickness, Inches

Thickness, Inches

1.25

1.12

1.00

1.50

1.38

1.19

1.75

1.56

1.38

2.00

1.81

1.62

2.25

2.00

1.81

2.50

2.25

2.00

F-43

|