| |

TM 10-3930-671-10

Before Operation

How To Perform the Daily Inspection

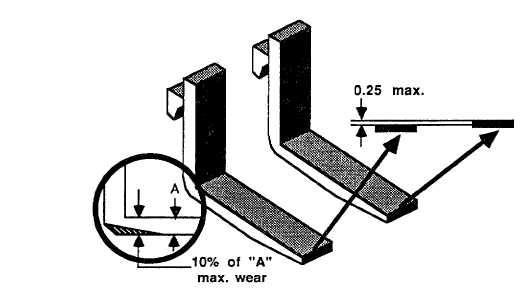

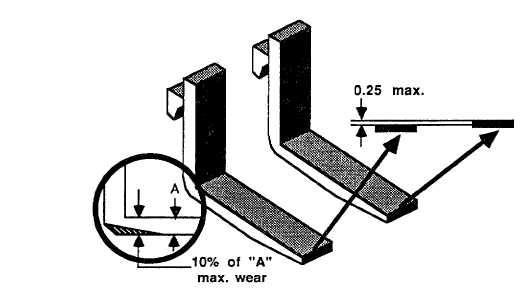

Inspect the lift forks for cracks, breaks, bending, and wear. The fork surfaces should be level and even with each other.

The height difference between both fork tops should be no more than (6 mm) 0.25 inch maximum. If the fork blade at the

heel of the fork is worn down by more than 10 percent, the load capacity of the forks is reduced and they must be

replaced.

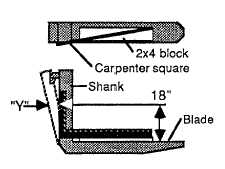

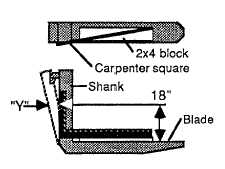

Inspect the forks for twists and bends. Put a 2"x4"x24" block on the

blade of the fork with the 4" surface against the blade. Put a carpenter

square on the top of the block and against the shank. Check the fork 18"

above the blade to make sure it is not bent more than specified in the

chart.

Fork

Allowable Y values for various blade lengths

Cross-section

42" blade

48" blade

54" blade

60" blade

1-1/2x4

15/16

1-1/4

1-9/16

1-15/16

1-3/4x5

1/2

5/8

25/32

31/32

To prevent accidental shifting of the forks, inspect the fork latches. Make

sure they are not damaged or broken, and that they operate freely and

lock correctly.

E-66

|