| |

TM 10-3930-669-34

WARNING

•

Fuel is very flammable and can explode easily. To avoid serious injury or

death, keep fuel away from open fire and keep fire extinguisher within easy

reach when working with fuel. Do not work on fuel system when engine is

hot. Fuel can be ignited by hot engine. When working with fuel, post signs

that read NO SMOKING WITHIN 50 FEET (15 m).

•

Pressure test procedure results in fuel under high pressure. Be sure that

pressure test gauge is connected properly and use safety shield during test.

Failure to do so may result in injury to personnel.

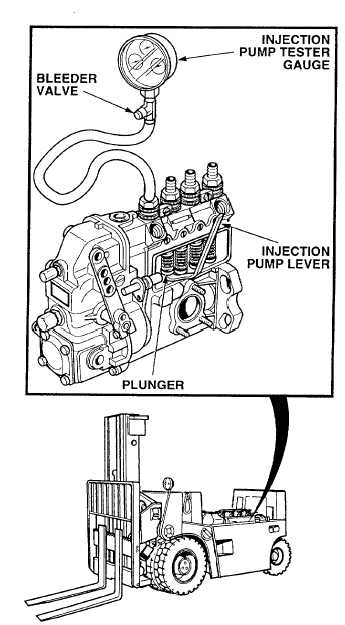

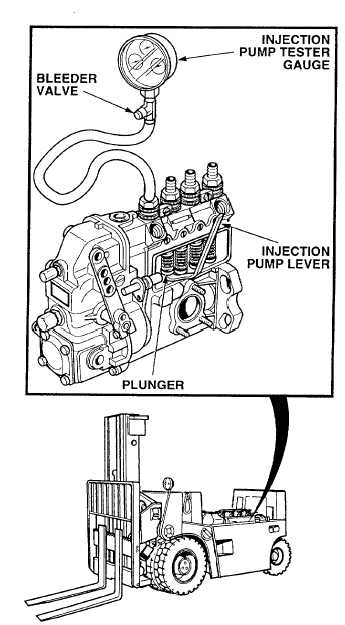

INJECTION PUMP PRESSURE TEST

(1)

Remove cab (TM 10-3930-669-20).

(2)

Disconnect throttle cable (TM 10-3930-669-20).

(3)

Position control lever to maximum position.

(4)

Remove pump cover(Para 4-5).

(5)

Tag and disconnect injection pump injector lines one

at a time.

(6)

Connect injection pump tester gauge to injection

pump port fitting.

(7)

Install pressure plug in No. 1 injector line.

(8)

Open bleeder valve on back of test gauge.

(9)

With aid of an assistant using retainer, turn

crankshaft clockwise until pump element to be

tested is at the bottom of its stroke.

(10)

Using pump lever, lift plunger to bleed air from

pressure gauge. Close bleeder valve.

(11)

Hold shutoff solenoid in open position and pump

lever until pressure gauge reads 2,175 psi (14,997

kPa).

(12)

Observe pressure gauge for 60 seconds.

(a)

If 145 psi (1,000 kPa) or higher is not

measured, perform Steps (14) and (15)

below and replace injection pump(Para 4-5).

(b)

If 145 psi (1,000 kPa) or higher is measured,

go to step (13) below.

(13)

Hold shutoff solenoid in open position and pump

lever until pressure gauge reads 5,075 psi (34,992

kPa).

(a)

If 5,075 psi (34,992 kPa) cannot be measured,

perform Steps (14) and (15) below and

replace injection pump(Para 4-5).

(b)

If 5,075 psi (34,992 kPa) can be measured,

repeat steps (5) through (13) above for

remaining elements. If all elements are OK,

perform Steps (14) and (15) below and go to

Step 2 of this Fault.

(14)

Remove injection pump tester gauge from pump

port fitting.

(15)

Install pump cover.

2-11

|