| |

TM 10-3930-669-34

4-5. INJECTION PUMP REPLACEMENT (CONT).

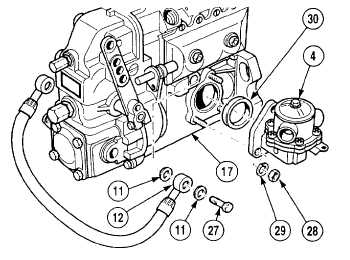

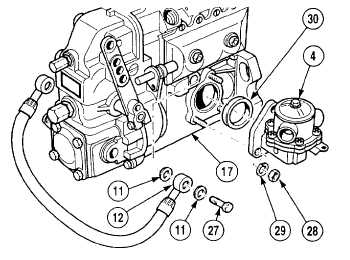

(13)

Remove screw (27), two seals (11), and oil line

(12) from injection pump (17). Discard seals.

(14)

Remove three nuts (28), lock washers (29), fuel

supply pump (4), and seal (30) from injection

pump (17). Discard three lock washers and

seal.

b. Cleaning/Inspection.

WARNING

·

Dry-cleaning solvent (P-D-680) is TOXIC and flammable. Wear protective goggles and gloves;

use only in a well-ventilated area; avoid contact with skin, eyes, and clothes; and do not

breathe vapors. Keep away from heat or flame. Never smoke when using solvent; the

flashpoint for type I dry-cleaning solvent is 100°F (38°C) and for type II is 138°F (50°C). Failure

to do so may result in injury or death to personnel.

·

If personnel become dizzy while using cleaning solvent, immediately get fresh air and medical

help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts eyes,

immediately flush eyes with water and get immediate medical attention.

(1)

Clean all metal parts with dry-cleaning solvent and wipe dry with wiping rag.

(2)

Inspect all parts for breaks, cracks, burrs, and sharp edges.

(3)

Replace all damaged parts.

c. Installation.

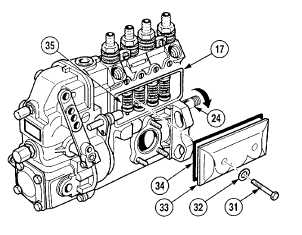

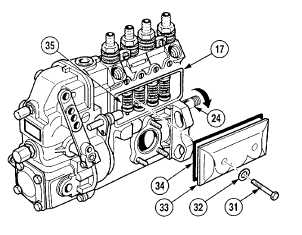

(1)

Remove two screws (31), preformed packing

(32), pump cover (33), and seal (34) from

injection pump (17). Discard seal and preformed

packings.

(2)

Turn injection pump shaft (24) counter-clockwise

until cylinder number one plunger (35) lifts.

(3)

Install pump cover (33) on injection pump (17)

with seal (34), two preformed packings (32), and

screws (31). Tighten screws to 7 Ib-ft (10 N•m).

4-20

|