| |

TM 10-3930-669-34

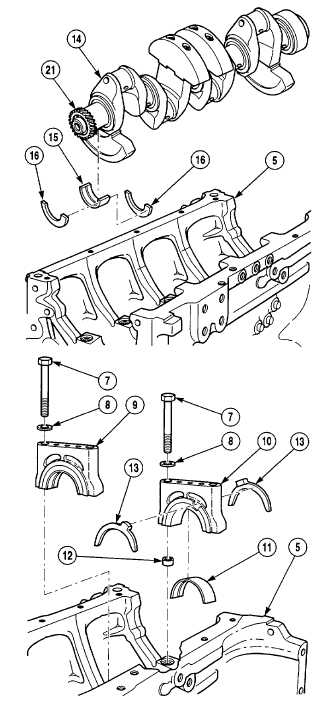

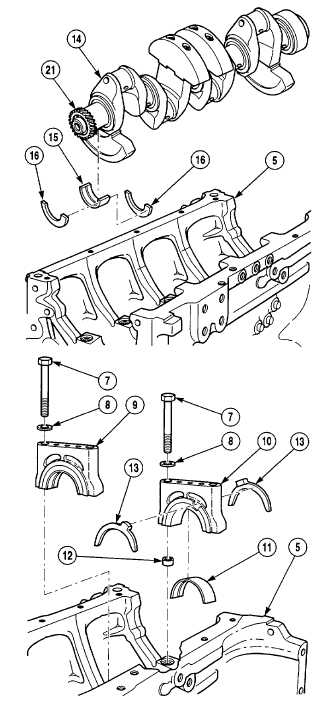

3-14. CRANKSHAFT REPLACEMENT/REPAIR (CONT).

e. Installation.

(1)

Apply grease on stop rings (16) and install

in matchmarked locations in crankcase

(5).

(2)

Install five bearing halves (15) in

crankcase (5), making sure that

matchmark locations are correct.

(3)

Using oil, lubricate crankshaft assembly

(14) journals and install with crankshaft

gear (21) matchmark positioned properly.

(4)

Apply grease on stop rings (13) and install

in matchmarked locations.

(5)

Install ten dowel bushings (12).

(6)

Install five bearing halves (11) in

matchmarked locations of bearing caps (9

and 10) making sure they are seated

properly.

NOTE

Start by tightening middle bearing

caps and finish with bearing caps at

ends. The crankshaft must be able to

rotate freely.

(7)

Install bearing caps (9 and 10), with their

matchmarked locations corresponding to

that of crankcase (5), install ten washers

(8) and ten screws (7). Preload screws

(7) to 22 lb-ft (30 N•m). Tighten screw

(see Appendix D).

3-80

|