| |

TM 10-3930-669-34

(4) Check cylinder liner seating on crankcase

surface and feel for any evidence of roughness.

Seating surface must be level and free from

grooves. If cylinder liner seat is not level and

free of grooves, repair liner(s) as follows:

(a)

Using a wiping rag, clean seating area and

remove paint residues.

(b)

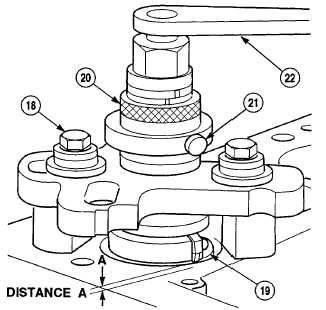

Center refacing device and tighten screws

(18).

(c)

Withdraw centering finger and slide tool

holder (19) out to diameter of cylinder

seating face.

CAUTION

•

DO NOT turn spindle counterclockwise when reworking surface or refacing

device will be damaged.

•

Adjust feed carefully. A full turn (360°) of knurled nut feeds tool holder 0.059

inch (1.5 mm).

(d)

Using knurled nut (20), turn spindle of turning device clockwise and adjust tool holder (19) specified amount

of liner face to be reworked.

(e)

Move tool holder (19) toward middle of bore.

(f)

Using knurled nut (20), set tool over and slightly beyond distance "A" to permit satisfactory refacing.

(g)

After adjusting tool, tighten setscrew (21).

NOTE

•

Selected cutting depth should not exceed 0.008 inch (0.2 mm). This feed

corresponds to a 1/8th turn (45°) of knurled nut. Less feed per cut will

produce a better surface.

•

Resurfacing cut should not exceed the cylinder height of 5.405 in. (137.7

mm).

(h)

Turn spindle (22) to rework seating area until smooth and/or flush with top of crankcase surface.

(i)

Set back tool holder and remove refacing device.

(j)

Clean crankcase thoroughly.

3-33

|