| |

TM 10-3930-669-34

3-4.

CRANKCASE REPAIR (CONT).

NOTE

•

If all bearings have a uniform

contact pattern, bearings are in

alignment.

•

Do

not

bore

out

individual

bearings.

(d)

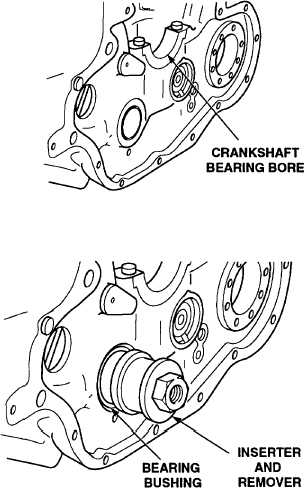

Rotate crankshaft. Remove screws,

washers, bearing caps, and crankshaft. If

bearing bores are in alignment, there will be

an even pattern of marking by crankshaft in

all bearing bores. If bearing bores require

alignment, bores must be line-bored.

(3) Using an inside micrometer, measure camshaft

bearing bores of crankcase. Bore should be 1.8890

to 1.8911 in. (47.9800-48.0340 mm). If bores are

more than 1.8890 to 1.8911 in. (47.9800-48.0340

mm), replace camshaft bearings as follows:

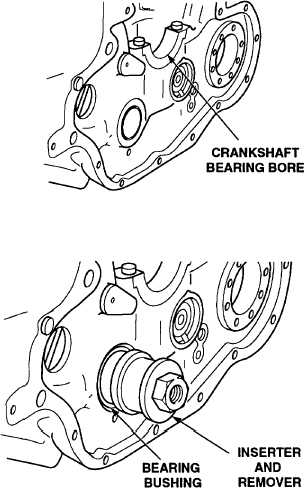

(a)

Install shorter, small-diameter thrust piece

(part of inserter and remover) on front end

of camshaft bore.

(b)

Install end support (part of inserter and

remover) at next camshaft bore.

(c)

Pull bearing bushing out towards flywheel

end.

CAUTION

Failure to align bearing/bushing oil holes with crankcase oil hole will result in

severe damage.

(d)

Align new camshaft bearing bushing so oil holes in bushing coincide with those in crankcase.

(e)

Using inserter and remover, press new bearing bushing into crankcase. Install bushing flush with front end of

crankcase.

(f)

Clean crankcase thoroughly.

3-32

|