| |

TM 10-3930-669-20

WARNING

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry contacts battery terminal, a

direct short may result in instant heating of tools, damage to equipment, and injury or death to

personnel.

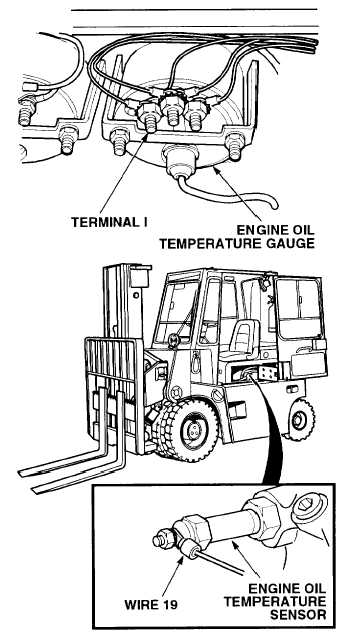

GAUGE OPERATION TEST

(1)

Set MAIN POWER switch to ON

position (TM 10-3930-669-10).

(2)

Set engine switch to ignition position

(TM 10-3930-669-10).

(3)

Observe gauge needle for reading.

(a)

If gauge does not have a full scale

deflection, perform Steps (4) through

(6) below.

(b)

If gauge has a full scale deflection,

perform Steps (5) and (6) below and

go to Step 3 of this Fault.

(4)

Install sensor wire 19 (Para 7-41).

(5)

Set engine switch to off position.

(6)

Set MAIN POWER switch to OFF

position.

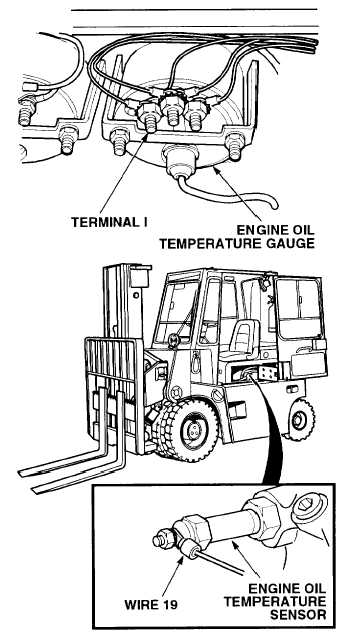

VOLTAGE TEST

(1)

Remove instrument panel (Para 7-8).

(2)

Set multimeter select switch to VOLTS DC.

(3)

Connect positive (+) multimeter lead to engine

oil temperature gauge, terminal I.

(4)

Connect negative (-) multimeter lead to a known

good ground.

(5)

Set MAIN POWER switch to ON position (TM

10-3930-669-10).

(6)

Set engine switch to ignition position (TM 10-

3930-669-10).

(a)

If there are not 22 to 24 vdc present,

perform Steps (7) and (8) below and

repair gauge wire 5 (see schematic

Appendix F).

(b)

If there are 22 to 24 vdc present, gauge

wire 5 is OK.

(7)

Set engine switch to off position.

(8)

Set MAIN POWER switch to OFF position.

2-85

|