| |

TM 10-3930-664-24

3.

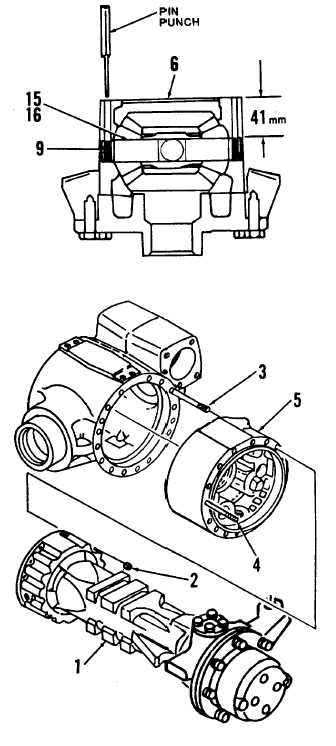

Rotate shaft (15) as required to align pin hole on

shaft with matching hole in gear case (6). Fully

install shaft.

4.

Insert pin (14) into gear case (6). Using a soft head

hammer and pin punch, drive pin half-way into shaft

(15) to secure shaft in case. Depth from face of

case to top of pins shall be 33 mm.

5.

Repeat steps 1 through 4 for two short shafts (16)

and remaining pinion gears and friction washers.

6.

Install bearing cone (8) onto sprocket (10).

7.

Install differential gear (13), friction washer (12), and

thrust bearing (11) into gear case (6).

8.

Apply loctite to threads of twelve bolts (9). Install

sprocket (10) onto gear case and secure using bolts.

Torque bolts to 52 to 55 ft-lbs (70 to 75 Nm).

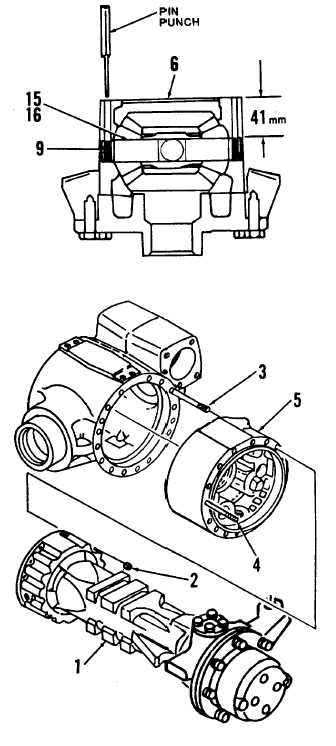

9.

Carefully install assembled differential gear case (1)

into axle housing (2).

10. Carefully install intermediate cover (5) onto studs (3).

Install two shouldered studs (4) into intermediate

cover.

11. Install axle case (1) onto studs (3, 4). Install sixteen

nuts (2) onto studs and torque to 25 ft-lbs. (34 Nm).

FOLLOW-ON MAINTENANCE:

Install tie rod (para. 4-30)

END OF TASK

4-73

|