| |

TM 10-3930-664-24

5.

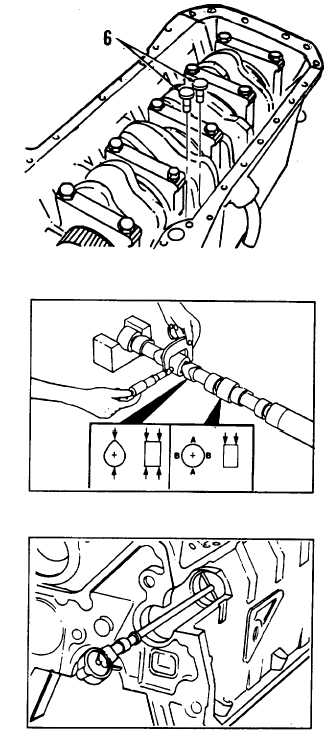

Reach into cylinder block and remove valve

tappets (6) from bores.

B.

CLEANING

Clean camshaft gear, camshaft, and valve tappets in

accordance with paragraph 1-24.

C.

INSPECTION

1.

Conduct overall inspection of camshaft gear,

camshaft, valve tappets, cylinder block, and

related

components

in

accordance

with

paragraph 1-24.

2.

Inspect camshaft lift pump lobe, valve lobes, and

bearing journals for wear, cracking, or pitting.

3.

Inspect camshaft gear teeth for wear and

damage. Inspect for broken or chipped teeth.

Check for cracks at the root of each tooth.

4.

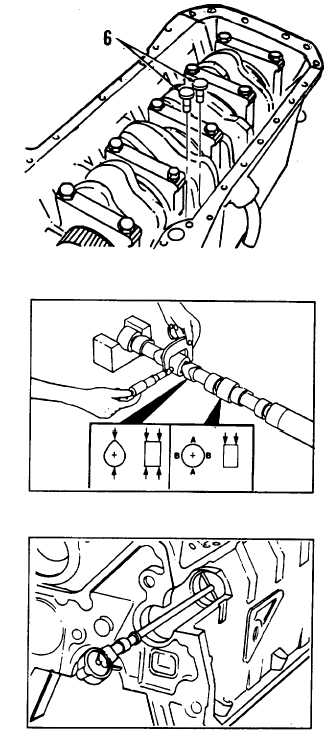

Measure camshaft journal diameter.

Diameter shall be at least 2.125 in. (53.96 mm).

5.

Measure

valve

lobe

diameter.

Minimum

diameter at peak of intake valve lobe shall be

1.852 in. (47.04 mm). Minimum diameter at

peak of exhaust valve lobe shall be 1.841 in.

(46.77 mm).

6.

Measure lift pump lobe diameter. Diameter shall

be at least 1.398 in. (35.50 mm).

7.

Inspect camshaft bore for damage or excessive

wear. Bore I.D. shall be a maximum of

2.131 in. (54.13 mm). Replace bushing if

beyond limit.

4-29

|