| |

TM 10-3930-664-24

6.

Inspect connecting rod for damage or excessive

wear. I-beam section must be free of dents or

other damage. Damage to I-beam can cause

stress risers which will progress to breakage.

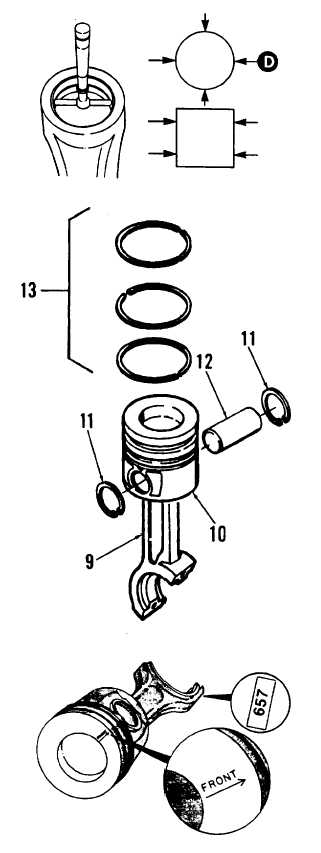

7.

Measure connecting rod pin bore (dimension D).

Maximum diameter shall be 1.5769 in.(40. mm).

D.

INSTALLATION

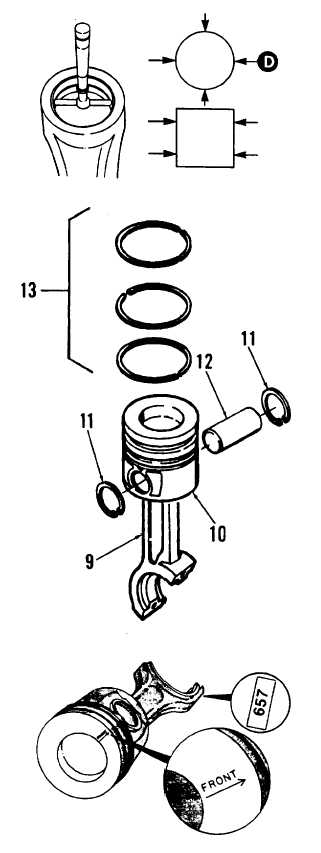

1.

Insert connecting rod (9) into piston (10). Ensure

FRONT marking on piston and identification

numbers on connecting rod are oriented as

shown in figure.

2.

Install retaining ring (11) into pin groove on

FRONT side of piston (10).

3.

Lubricate pin (12) and pin bore with oil. Insert pin

into piston (10) and secure using second

retaining ring (11).

4.

Determine diameter of piston (1) and obtain

proper ring set (13).

5.

Position each ring of set (13) into cylinder.

Distance from top of cylinder head to bottom ring

shall be 3.5 in. (89 mm). Use piston to square

rings with bore.

6.

Using a feeler gage, measure gap. Gap shall be

0.0100 to 0.0215 in. (0.25 to 0.55 mm) for each

ring.

4-24

|