| |

TM 10-3930-664-24

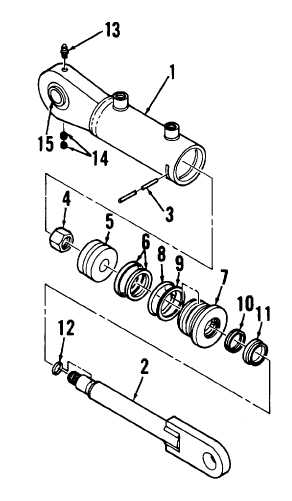

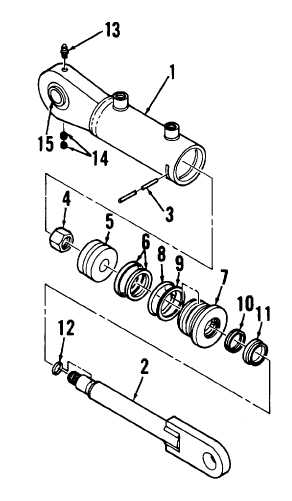

3-69. ROTATE CYLINDER REPAIR

This task covers: Disassembly, Cleaning, Inspection, Repair, and Assembly

INITIAL SETUP:

Tools and Test Equipment:

Equipment Condition:

General Mechanics Tool Kit (1, App. E)

Rotate cylinder removed

Torque Wrench (32, App. E)

(para. 2-161)

Spanner Wrench (31, App. E)

Materials / Parts:

Lubricating Fluid (16, App. C)

Grease (10, App. C)

Emery Cloth (7, App. C)

Seal Kit, P/N 6965-34 (1 ea.)

A. DISASSEMBLY

1.

Place cylinder clevis in a vice with clevis

perpendicular to vise jaws. Support cylinder

barrel (1). Pull rod assembly (2) out of barrel

until completely extended.

2.

Using a screwdriver, pry up lockwire (3) to

enable removal from freelift cylinder. Using a

spanner

wrench,

unscrew

gland

(7)

until

,lockwire is completely removed.

CAUTION

Use

care

when

extracting

and

handling rod assembly components

to prevent damage.

3.

Remove rod assembly (2) from barrel (1) and

place clevis end of rod assembly in a vise with

soft metal jaws. Support rod assembly.

4.

Remove nut (4) from rod assembly (2). Remove

piston (5) and gland (7).

5.

Remove and discard piston seal (6), O-ring (8),

backup ring (9), seal (10), wiper (11), and O-ring

(12).

6.

Remove grease fitting (13) and setscrews (14).

Remove bearing (15).

3-230

|