| |

TM 10-3930-664-24

4.

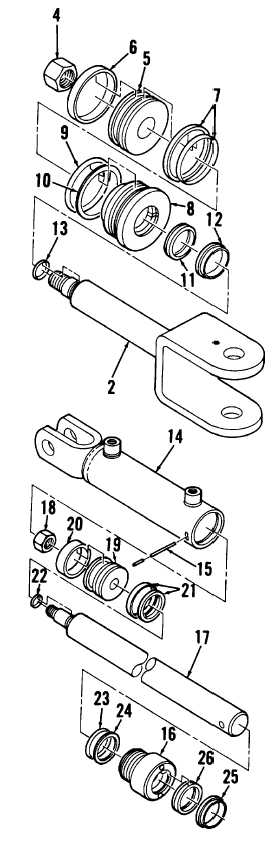

Remove nut (4) from rod assembly (2). Remove

piston (5) and gland (8).

5.

Remove and discard wear ring (6), piston seal

(7), O-ring (9), backup ring (10), seal (11), wiper

(12), and O-ring (13).

B. DISASSEMBLY OF MAIN LIFT CYLINDER

1.

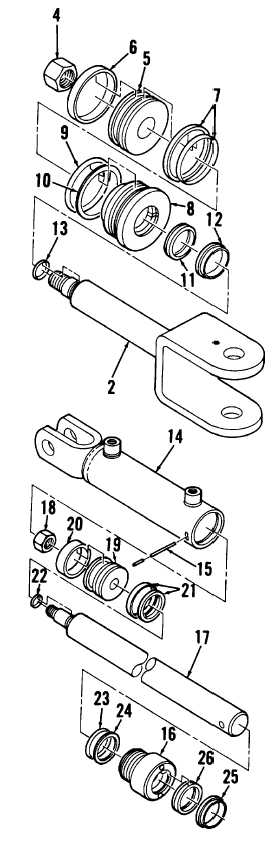

Place cylinder clevis in a vice with clevis

perpendicular to vise jaws. Support cylinder

barrel (14). Pull rod assembly (17) out of barrel

until completely extended.

2.

Using a screwdriver, pry up lockwire (15) to

enable removal from freelift cylinder. Using a

spanner wrench, unscrew gland (16) until

lockwire is completely removed.

CAUTION

Use

care

when

extracting

and

handling rod assembly components

to prevent damage.

3.

Place pin through hole in rod assembly (17) and

against vise to keep rod assembly from turning.

Remove rod assembly from barrel (14) and

place in a v: se with soft metal holders.

4.

Remove nut (18) from rod assembly (17).

Remove piston (19) and gland (16).

5.

Remove and discard wear ring (20), piston seal

(21), and O-ring (22).

6.

Remove and discard O-ring (23), backup ring

(24), wiper (25), and seal (26).

C. CLEANING

Clean lift cylinder components in accordance with

paragraph 1-24.

D. INSPECTION

1.

Conduct

overall

inspection

of

lift

cylinder

components in accordance with paragraph 1-24.

2.

Inspect used piston seals for signs of scoring. If

seals are scored, examine barrel for damage. If

barrel is scored it must be replaced.

3-225

|