| |

TM 10-3930-664-24

B. CLEANING

Clean carriage tilt cylinder components in accordance

with paragraph 1-24.

C. INSPECTION

1.

Conduct overall inspection of carriage tilt cylinder

components in accordance with paragraph 1-24.

2.

Inspect used piston seals for signs of scoring. If

seals are scored, examine barrel for damage. If

barrel is scored it must be replaced.

D. REPAIR

1.

Repair of the carriage tilt cylinder consists of

removal and replacement of defective,

deformed, or damaged components.

2.

Replace all rings, wipers, and seals with new

components from seal kit.

E. ASSEMBLY

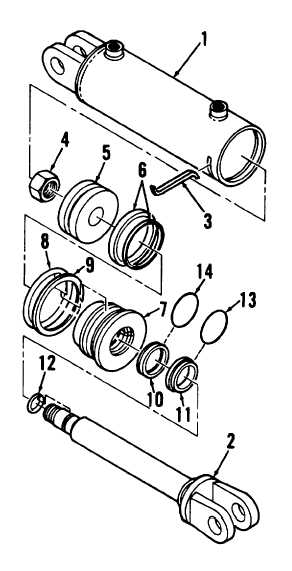

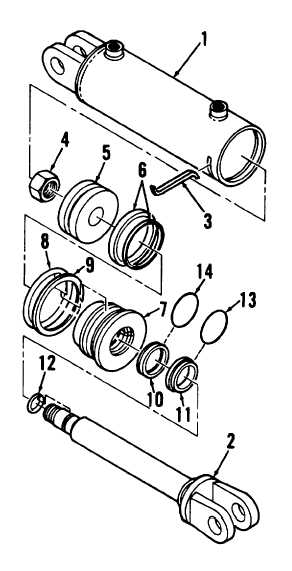

1.

Lubricate new O-ring (12) with clean

lubricating oil and install onto rod assembly (2).

2.

Lubricate new O-ring (13) with clean

lubricating oil and install into gland (7). Install

new seal (14).

NOTE

Warming seal (10) in warm water may

make it easier to install. Bend seal

and insert seal into gland (7). Seat

seal

using

rounded

portion

of

screwdriver or similar tool.

3.

Install new seal (14), wiper (11), seal (10), and

backup ring (9) onto gland (7). Lubricate new O-

ring (8) with clean lubricating oil and install.

4.

Install new piston seal (6) onto piston (5).

5.

Lubricate I.D. of gland (7) and piston (5) with

lubricating oil and install onto rod assembly (2)

with wear ring nearest nut (4).

6.

Apply loctite to threads of rod assembly (2).

Install nut (4) and torque to 253 to 279 ft-lbs (340

to 376 Nm).

3-212

|