| |

TM 10-3930-664-24

A.

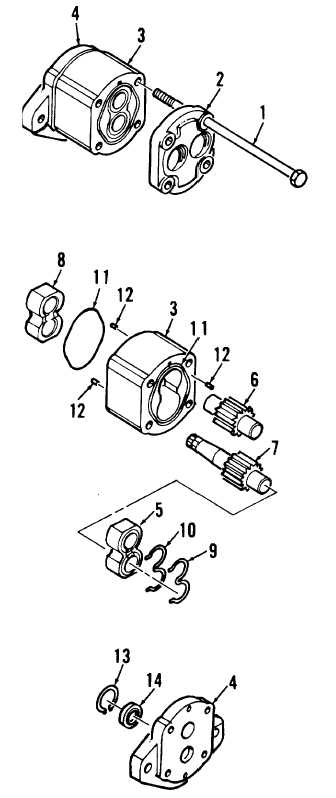

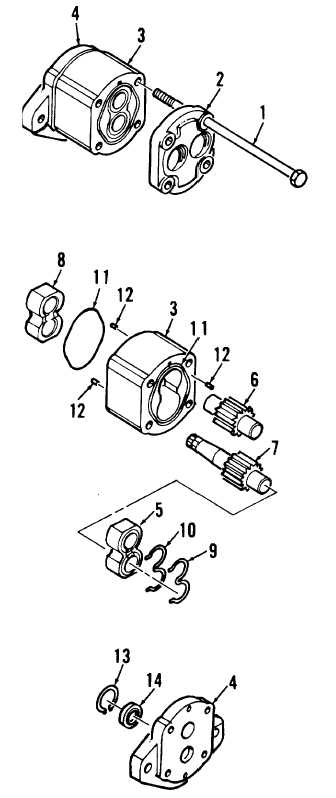

DISASSEMBLY

1.

Tape end of shaft to prevent damage to oil seal

during shaft removal.

2.

Remove four bolts (1) and remove end cover (2)

from gear housing (3). Set end cover aside.

3.

Match mark inlet side of gear housing (3) to

mounting flange (4) to aid in installation.

4.

Separate gear housing (3) from mounting flange (4),

making sure that bearing block remain with shafts.

5.

Remove rear bearing block (5) from drive and idler

gear shafts.

6.

Remove idler shaft (6) from gear housing (3).

Carefully remove drive shaft (7) from gear housing,

making sure not to damage components.

7.

Remove front bearing block (8) from gear housing

(3).

8.

Place bearing blocks (5, 8) on a clean work surface,

E-seals (9) facing up. Remove E-seals and backup

rings (10) from bearing blocks and discard.

9.

Remove O-rings (11) from gear housing (3) and

discard. Remove dowel pins (12) only if replacement

is required.

CAUTION

Use care when removing oil seal (14)

to

prevent

damage

to

mounting

flange (4). Scratches in seal bore will

cause

leakage

and

require

replacement of mounting flange.

10. Place mounting flange (4) on a clean work surface,

seal retaining ring (13) facing up. Carefully remove

retaining ring and oil seal (14) from mounting flange.

Discard oil seal.

3-202

|