| |

TM 10-3930-664-24

B.

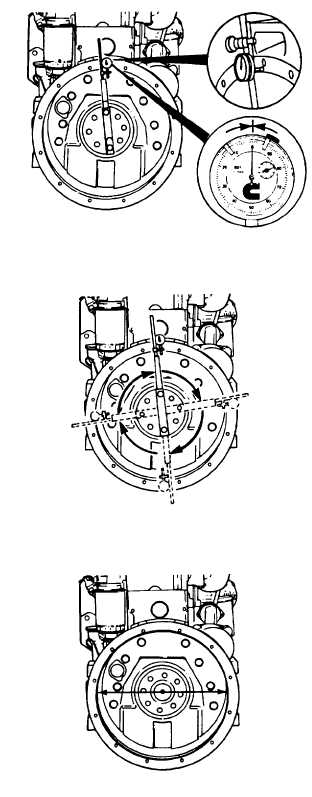

HOUSING FACE ALIGNMENT CHECK

1.

Attach dial indicator to crankshaft as shown in

figure. Indicator extension bar must be rigid for

accurate readings. If the extension bar sags or

the indicator slips, readings will not be accurate.

CAUTION

Dial indicator tip must not enter cap

screw holes or dial indicator will be

damaged.

2.

Move dial indicator to 12 o’clock position. Adjust

dial until needle points to zero.

NOTE

Each time a position is measured, the

crankshaft must be pushed toward front

of engine to eliminate crankshaft end

clearance.

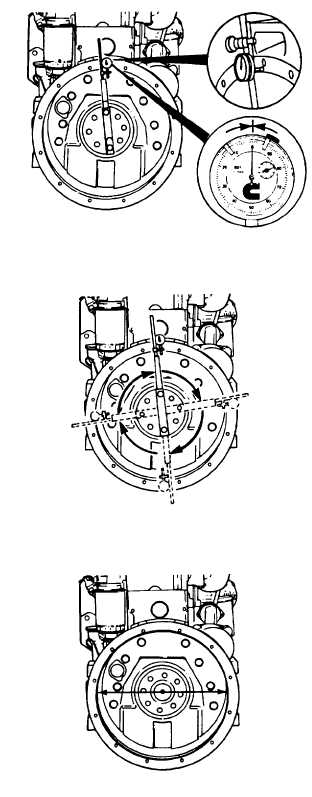

3.

Slowly rotate crankshaft. Record dial readings

at 3, 6, and 9 o’clock positions.

4.

Continue to rotate crankshaft until dial indicator

is at 12 o’clock position. Check indicator to

ensure needle points to zero.

5.

Calculate total indicator reading (TIR) as follows

(numbers are for example only):

12 O’Clock Reading -

+ 0.000 IN.

+

3 O’Clock Reading =

+ 0.003 IN.

+

6 O’Clock Reading =

- 0.002 IN.

+

9 O’Clock Reading =

+ 0.003 IN.

Equals TIR

+ 0.005 IN.

6.

TIR reading for face alignment check shall not

exceed 0.008 inch. If TIR exceeds 0.008 inch,

housing face is out of alignment and housing

must

be

replaced.

3-41

|