| |

TM 10-3930-664-24

CAUTION

Use care when raising crankshaft to

prevent damage.

Do

not

force

crankshaft beyond the point where

bearing clearance has been removed.

6.

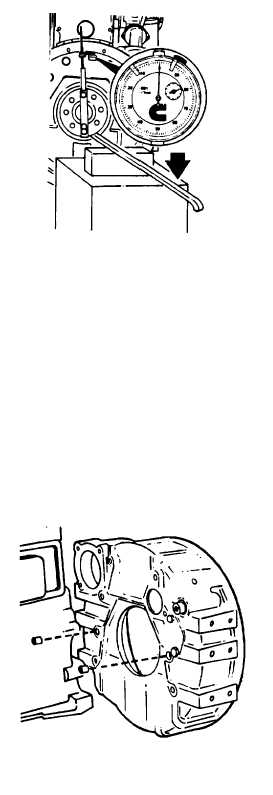

Using a floor mounted support and padded pry

bar, raise rear of crankshaft to its upper limit.

7.

Record new dial reading at 12 o’clock position.

New

reading

indicates

vertical

bearing

clearance.

8.

Calculate a "total horizontal" value by subtracting

the 3 o’clock reading (step 3) from the 9 o’clock

reading:

9 o’clock reading

- 3 o’clock reading

= total horizontal value

9.

Calculate a "total vertical" value by adding the 12

o’clock reading (step 3) to the vertical bearing

clearance (step 7):

12 o’clock reading

+ vertical bearing clearance

= total vertical value

10.

Mark the "total horizontal" value on horizontal

side of adjacent chart. Mark the total vertical"

value on vertical side.

11.

Using a straight edge, find the intersection point

of the two values. Intersection point must fall

within shaded area of chart.

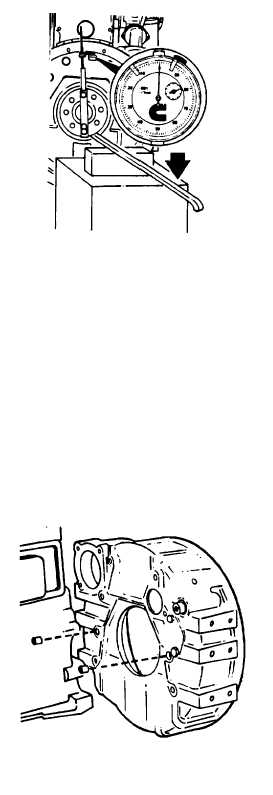

12.

If intersection falls outside shaded area on chart,

housing concentricity is not within specifications.

Remove flywheel housing (paragraph C) and

remove dowel rings.

13.

After dowel rings are discarded, reinstall flywheel

housing. Tighten capscrews enough to hold

housing in place, but loose enough to allow small

movement when struck lightly with a mallet.

14.

Recheck concentricity. Torque capscrews.

3-40

|