| |

TM 10-3930-664-24

3-10.

FLYWHEEL HOUSING REPLACEMENT

This task covers: Housing Bore Check, Housing Face Alignment Check, Removal, Cleaning, Inspection, and Installation

INITIAL SETUP:

Tools and Test Equipment:

Equipment Condition:

General Mechanics Tool Kit (1, App. E)

Flywheel and rear seal removed

Dial Indicator Set (17, App. E)

(para. 3-9)

Soft Head Hammer (23, App. E)

Materials / Parts:

Sealant (29, App. C)

Rear Cover Gasket, Item 12 (1 ea.)

O-Ring, Item 10 (1 ea.)

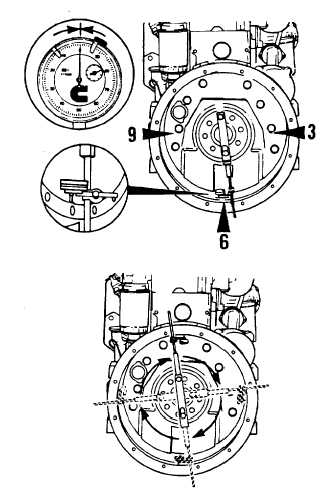

A.

FLYWHEEL HOUSING BORE CHECK

1.

Attach dial indicator to crankshaft as shown in

figure. Indicator extension bar must be rigid for

accurate readings. If the extension bar sags or

the indicator slips, readings will not be accurate.

2.

Move dial indicator to 6 o’clock position. Adjust

dial until needle points to zero.

3.

Slowly rotate crankshaft. Record dial readings

at 9, 12, and 3 o’clock positions.

NOTE

Dial readings at 9, 12, and 3 o’clock

positions

may

be

positive

or

negative.

4.

Continue to rotate crankshaft until dial indicator

is at 6 o’clock position. Check indicator to

ensure needle points to zero.

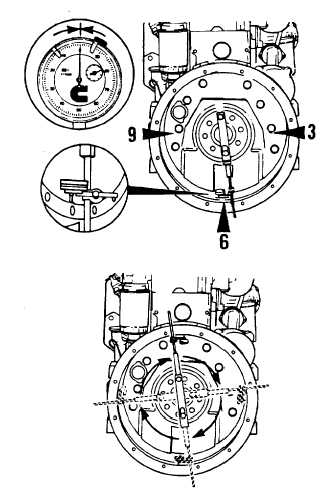

5.

Rotate crankshaft until dial indicator is at 12

o’clock position. Adjust dial until needle points to

zero.

3-39

|