| |

TM 10-3930-664-24

C.

INSPECTION

1.

Inspect cylinder head and related components

in accordance with paragraph 1-24.

2.

Inspect coolant passages for blockage. A large build

up of rust and lime will require removal of cylinder

block for cleaning in a hot tank.

3.

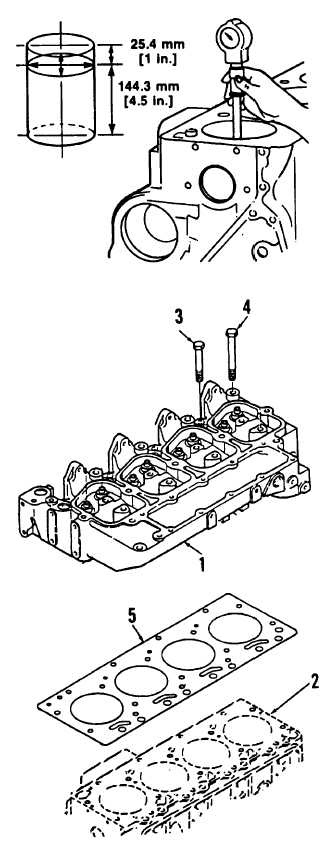

Inspect cylinder bores for damage and excessive

wear. Manually rotate crankshaft so that the piston

for bore being inspected is at bottom of bore.

4.

Measure cylinder bores as follows (refer to figure):

a.

Maximum bore I.D. shall be 4.0203 in. (102.116

mm).

b.

Out of round shall not exceed .0015 in. (.038

mm).

c.

Taper shall not exceed .003 in. (.076 mm).

5.

Check top surface of cylinder block for damage

caused by leaking cylinder head gasket.

6.

Check top surface of cylinder block for flatness

between cylinders. Variance shall not exceed .002

in. (.050 mm).

7.

Do not proceed with cylinder head replacement

if crankcase is damaged or tolerances in steps 4 and

6 are not met. Remove engine from service and

send to depot maintenance shop for overhaul.

D.

INSTALLATION

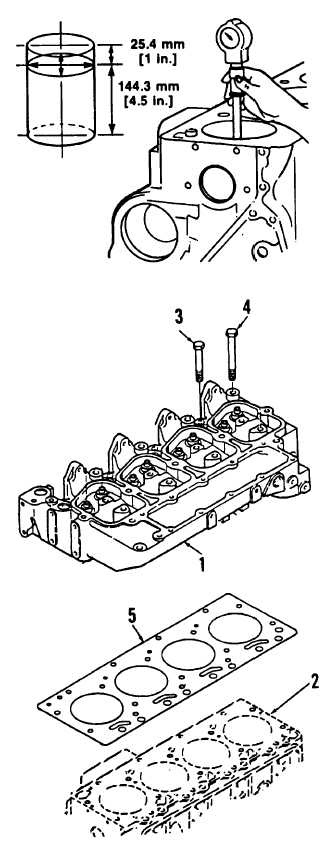

1.

Mate new gasket (5) to engine cylinder block (2).

Ensure gasket fits properly over cylinder block

dowels.

2.

Carefully install cylinder head (1) onto dowels.

3.

Lubricate threads of screws (3, 4) with oil. Install four

screws (3) and ten screws (4) to secure cylinder

head (1). Hand tighten screws.

3-34

|