| |

TM 10-3930-664-24

3.

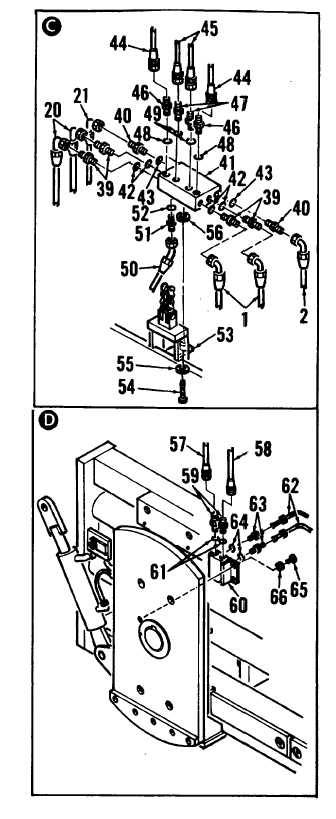

TAG AND DISCONNECT HOSE ASSEMBLIES

(1, 2, 20, 21, 44, 45, 50) FROM INTERMEDIATE

RAIL MANIFOLD (41).

4.

REMOVE INTERMEDIATE RAIL MANIFOLD

(41) AND ADAPTERS.

NOTE

Tension of hose assemblies (44, 45) is

determined by position of intermediate

rail manifold (24). Position of manifold

is adjusted by adding or subtracting

washers (56) between bracket and

manifold. When removing manifold,

record number of washers (55, 56)

between bracket and manifold and

between bracket and head of screw

(54). It is important that the same

number of washers are used during

installation.

a.

Remove intermediate rail manifold (41)

from inner rail by removing screw (54) and

washers (55, 56).

b.

Remove adapters (39, 40, 46, 47, 51) from

intermediate rail manifold (41).

c.

Remove and discard O-rings (42, 43, 48,

49, 52).

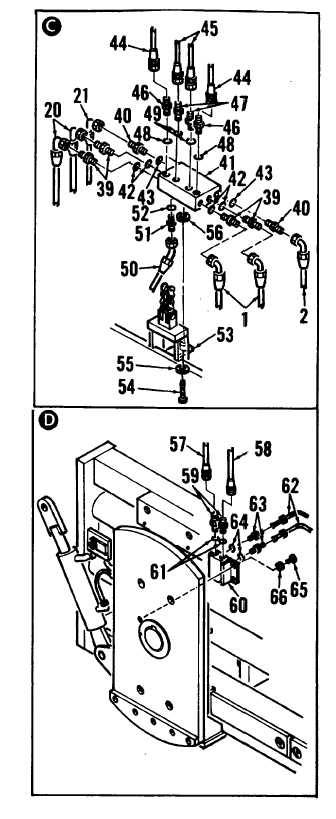

5.

DISCONNECT HOSE ASSEMBLIES (57, 58)

AND TUBE ASSEMBLIES (62) FROM SPINE

MANIFOLD (60). REMOVE SPINE

MANIFOLD AND ADAPTERS.

a.

Remove mud guard from sideshift

carrier by removing attaching screws,

washers, and spacers.

b.

Tag and disconnect hose assemblies (57,

58) from fittings (59).

c.

Remove fittings (59) from spine manifold

(60). Remove and discard O-rings (61).

d.

Tag and disconnect tube assemblies (62)

from adapters (63).

e.

Remove adapters (63) from spine

manifold (60). Remove and discard O-

rings (64).

f.

Remove spine manifold (60) from spine

assembly by removing screws (65) and

washers (66).

2-400

|